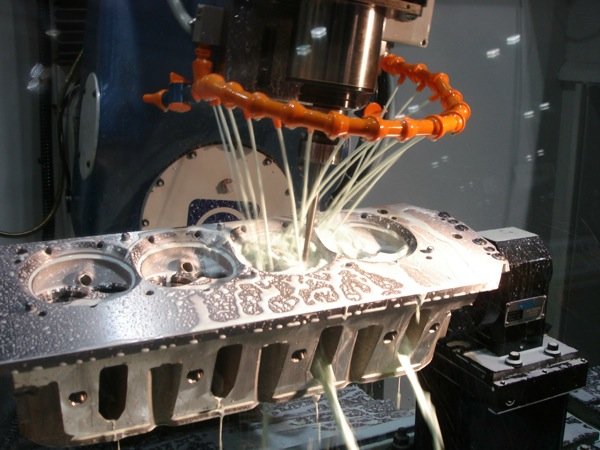

CNC Machining is critical in achieving high-performance engines, especially when manufacturing cylinder heads. Cylinder heads are among the most precision-sensitive components in automotive, machine building, and automotion applications. Proper machining can significantly improve airflow, combustion efficiency, and engine longevity. In this article, we explore 10 powerful ways precision CNC machining cylinder heads improve engine performance, offering deep insights, practical solutions, and guidance for engineers and manufacturers. At CNCRUSH, we provide professional CNC machining services with over 12 years of experience in producing high-quality CNC Milled parts and CNC Turned parts, ensuring every engine component meets strict performance standards.

1. Enhancing Airflow Through Precision CNC Machining

Cylinder head efficiency depends heavily on smooth and accurately machined intake and exhaust ports. Uneven surfaces or tool marks can disrupt airflow, reducing engine power. Precision CNC machining addresses these issues:

-

Optimizes port shape for maximum air-fuel mixture efficiency

-

Reduces turbulence that can cause uneven combustion

-

Improves volumetric efficiency for better horsepower output

CNCRUSH Advantage: Our CNC Milled parts and CNC Turned parts are manufactured with precise tolerances, ensuring smooth flow passages and consistent engine performance across automotive, machine building, and automotion applications.

2. Improving Valve Seating and Combustion Efficiency

Valve seat alignment is critical for proper sealing during combustion. Misaligned or rough valve seats lead to leaks, incomplete combustion, and reduced efficiency. CNC machining allows:

-

Perfect alignment of intake and exhaust valves

-

High-precision surface finish for better sealing

-

Optimized valve angles to increase power output

By using our 12 years of CNC machining experience, CNCRUSH guarantees CNC Milled parts and CNC Turned parts with tight tolerances, enhancing both efficiency and engine reliability.

3. Reducing Thermal Stress with Accurate Machining

Thermal distortion can reduce engine lifespan and performance. Improperly machined cylinder heads are prone to warping under heat cycles. CNC machining helps:

| Problem | Impact | CNC Solution |

|---|---|---|

| Uneven surface | Warped head | Precision milling for flatness |

| Poor hole alignment | Misfiring | Accurate drilling and turning |

| Excessive residual stress | Cracks | Controlled stress-relief processes |

CNCRUSH applies precise thermal management and stress-relief techniques to all CNC Milled parts and CNC Turned parts, ensuring durability under high temperatures.

4. Optimizing Combustion Chamber Design

The combustion chamber shape influences flame propagation and engine efficiency. CNC machining enables:

-

Accurate reproduction of complex chamber geometries

-

Consistent surface finishes that minimize hot spots

-

Improved power output and fuel efficiency

Analysis: Properly machined CNC Milled parts allow engines to achieve higher compression ratios without pre-ignition issues, improving both performance and reliability.

5. Enhancing Cylinder Head Structural Integrity

Cylinder heads must withstand high pressure and thermal loads. CNC machining ensures structural integrity by:

-

Removing casting imperfections and porosity

-

Reinforcing critical areas without adding unnecessary weight

-

Maintaining flatness and dimensional accuracy

CNCRUSH Expertise: Our CNC machining service produces CNC Milled parts and CNC Turned parts with consistent strength and rigidity, vital for automotive and machine-building applications.

6. Increasing Engine Durability and Longevity

Precise machining prevents premature wear in moving parts. Issues like valve misalignment, uneven surfaces, and poor thread integrity are common causes of failure. CNC machining ensures:

-

Accurate valve guides for smooth operation

-

Correct thread machining for reliable assembly

-

Uniform surface contact to reduce wear

By choosing CNCRUSH, clients receive high-quality CNC Milled parts and CNC Turned parts that extend engine lifespan, reflecting our 12-year commitment to excellence.

7. Minimizing Performance Loss with Consistent Quality

Even small deviations in cylinder head dimensions can lead to substantial performance loss. CNC machining provides:

| Deviation | Effect | CNC Solution |

|---|---|---|

| 0.05mm misalignment | Loss of compression | Precision milling and turning |

| Surface roughness | Reduced airflow | Controlled finishing passes |

| Port diameter variation | Uneven combustion | Tight tolerance CNC machining |

CNCRUSH ensures every CNC Milled part and CNC Turned part meets stringent specifications, maintaining engine performance in automotive and automotion industries.

8. Supporting High RPM Applications

High-performance engines often operate at elevated RPMs, where small imperfections amplify stress. CNC machining allows:

-

Perfectly balanced ports and chambers

-

Precise alignment of valve seats and guides

-

Reduced turbulence for smoother high-speed operation

Our CNC machining service ensures CNC Milled parts and CNC Turned parts can handle high RPM conditions reliably, providing a performance boost without compromising durability.

9. Facilitating Aftermarket Modifications and Performance Tuning

Engine builders and automotive enthusiasts require precise machining for modifications. CNC machining supports:

-

Accurate reshaping of ports and chambers

-

High-precision valve seat alterations

-

Consistency for repeatable performance upgrades

CNCRUSH’s CNC Milled parts and CNC Turned parts meet tight tolerances for both OEM replacements and aftermarket performance applications, enhancing engine output.

10. Integrating Advanced Manufacturing Techniques

Modern engine design demands advanced machining approaches, including 5-axis CNC milling, multi-spindle turning, and adaptive cutting. CNC machining enables:

-

High-precision complex geometries

-

Reduced production errors and scrap

-

Faster turnaround without compromising quality

CNCRUSH Advantage: Our 15 3-axis machines, 5 4-axis machines, and 5 5-axis machines, coupled with professional inspection equipment, ensure CNC Milled parts and CNC Turned parts are manufactured efficiently and reliably.

FAQ: CNC Machining Cylinder Heads

Q1: How does CNC machining improve airflow in cylinder heads?

A: CNC machining creates smooth, precise intake and exhaust ports, reducing turbulence and increasing volumetric efficiency.

Q2: Can CNCRUSH handle high-volume production?

A: Yes, our extensive machinery and 12 years of experience allow large-scale production of CNC Milled parts and CNC Turned parts with consistent quality.

Q3: What materials can be used for cylinder heads?

A: Aluminum alloys, cast iron, and specialty alloys. CNCRUSH can handle all materials common in automotive and industrial applications.

Q4: Why choose CNCRUSH for cylinder head machining?

A: With over 12 years of CNC machining experience, advanced machines, and precise quality control, CNCRUSH guarantees reliable, high-performance CNC Milled parts and CNC Turned parts for automotive, machine building, and automotion industries.

By understanding and implementing precision CNC machining techniques, engine builders can significantly improve power, efficiency, and longevity. CNCRUSH’s professional CNC machining service ensures every component meets high standards, making us a trusted partner in the automotive, machine building, and automotion sectors.