CNC Milling is the foundation of precision manufacturing for rocker arms, combining high-accuracy milling and drilling processes to ensure strength, durability, and flawless motion in automotive, machine building and automotion applications.

Overview: What the Original Sources Reveal About Rocker Arm Machining

Across the referenced materials, one key message stands out clearly: rocker arms demand extreme precision. Whether the discussion focuses on drilling mechanics, milling setups, machine kinematics, or real-world machining challenges, the shared intent behind these articles is to help engineers and manufacturers avoid costly errors, improve surface integrity, and ensure consistent performance in high-load environments.

Rocker arms are not simple components. They operate under cyclic stress, require precise hole alignment, and depend heavily on surface finish quality. CNC milling and drilling are therefore not optional processes — they are mission-critical manufacturing steps.

This article expands on those insights, translating them into a structured, professional guide backed by 12 years of CNC machining service experience from CNCRUSH, a trusted China-based manufacturer specializing in CNC Milled parts and CNC Turned parts.

CNC Milling for Rocker Arms: Why Precision Defines Performance

CNC Milling plays a decisive role in shaping rocker arms, especially when tight tolerances and complex geometries are involved. Even a minor deviation can introduce uneven load distribution, accelerated wear, or catastrophic failure.

Rocker arms used in automotive and automotion systems must meet three critical demands:

-

Structural rigidity

-

Accurate pivot geometry

-

Long-term fatigue resistance

At CNCRUSH, our CNC machining service focuses on multi-axis CNC milling strategies that maintain geometric consistency while optimizing cutting forces. This reduces residual stress — a common negative factor often overlooked in basic machining discussions.

CNC Milling and Drilling for Rocker Arms: Understanding Material Behavior

Material selection directly influences how CNC Milling and drilling parameters are defined. Aluminum alloys, alloy steel, and hardened steels each respond differently to tool pressure, heat, and chip evacuation.

A positive machining outcome depends on:

-

Proper spindle speed tuning

-

Controlled feed rates

-

Stable fixturing

Our CNC machining service frequently supports automotive and machine building customers by selecting optimal tool paths that minimize vibration and improve surface integrity, particularly in deep drilling operations common in rocker arm designs.

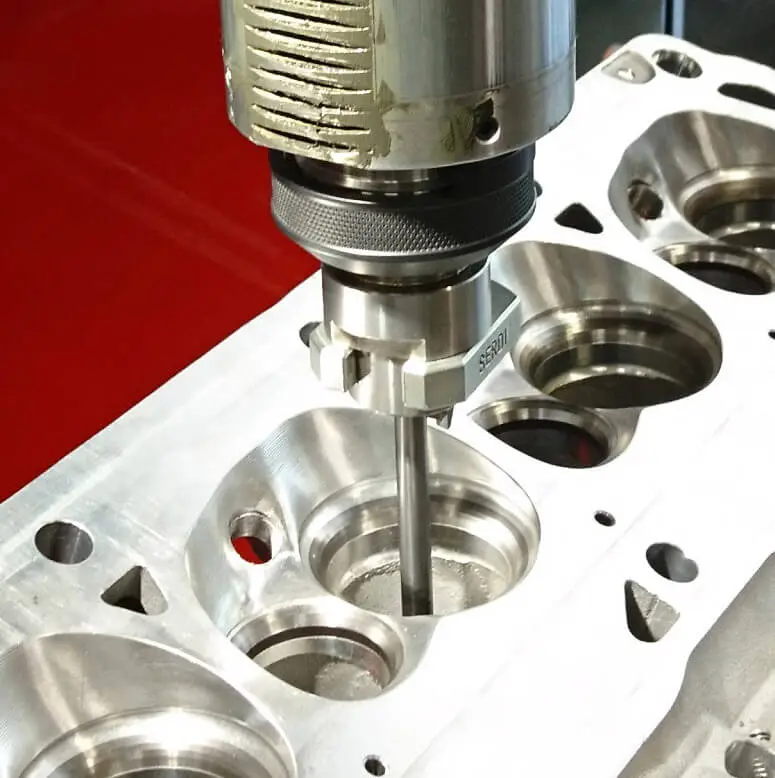

CNC Milling and Drilling Accuracy: Hole Alignment Challenges

One of the most critical features of rocker arms is hole alignment. Misaligned drilled holes result in uneven bearing contact, leading to early failure.

CNC Milling ensures:

-

Accurate face referencing

-

Flatness control before drilling

-

Consistent datum positioning

By combining CNC Milled parts processes with precision drilling, CNCRUSH ensures that rocker arms meet demanding automotion standards without compromising structural balance.

CNC Milling Strategies for High-Stress Rocker Arm Zones

Not all areas of a rocker arm experience equal stress. Load-bearing zones require:

-

Enhanced surface finish

-

Rounded transitions

-

Stress-relief machining paths

Advanced CNC Manufacturing techniques such as adaptive clearing and trochoidal milling significantly reduce tool pressure. This is especially valuable in high-stress automotive applications where fatigue failure is a constant concern.

CNC Milling Surface Finish and Its Emotional Impact on Quality

Surface finish is often underestimated, yet it has a profound emotional impact on engineers and buyers alike. A poor finish signals risk. A clean, consistent finish builds trust.

CNC Milling improves:

-

Oil retention characteristics

-

Friction behavior

-

Visual inspection confidence

At CNCRUSH, our CNC machining service places strong emphasis on surface finish control because we understand that confidence in quality is just as important as dimensional accuracy.

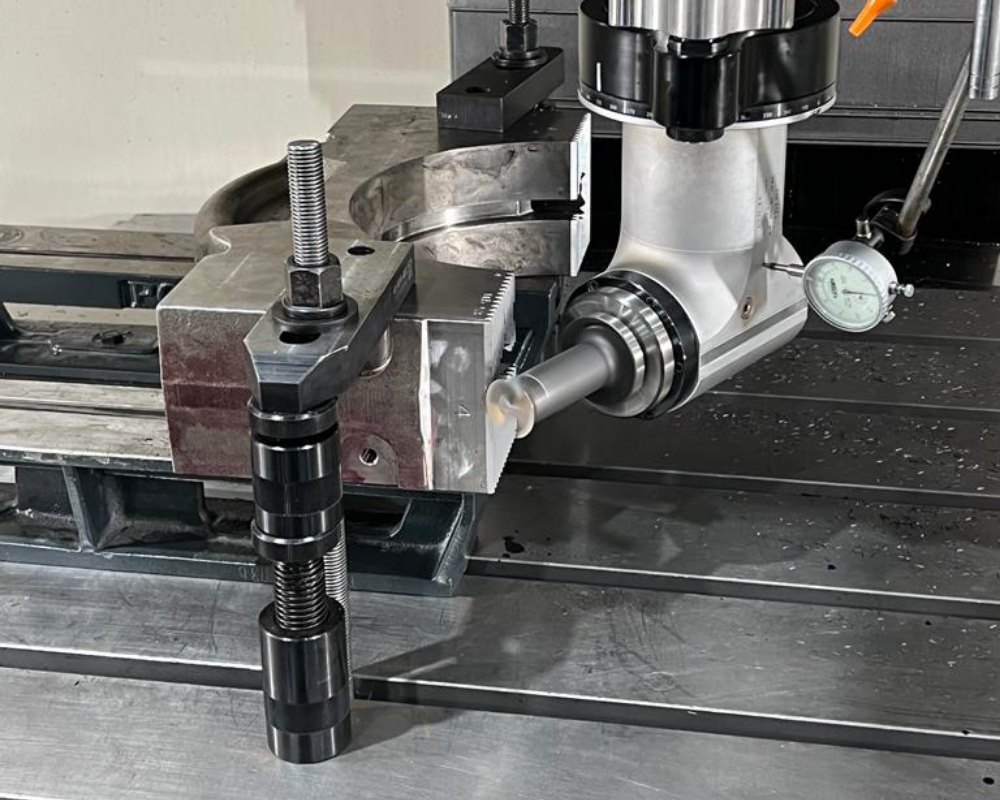

CNC Milling and Drilling Machine Stability Factors

Machine rigidity is a hidden but powerful variable. Unstable setups cause chatter, dimensional drift, and tool wear.

Professional CNC Manufacturing setups require:

-

Rigid machine frames

-

Proper fixture design

-

Balanced tool holders

Our factory leverages industrial-grade CNC machines specifically chosen to support precision CNC Milled parts and CNC Turned parts for long production cycles.

CNC Milling Tool Selection for Rocker Arms

Tool geometry directly affects cutting efficiency and surface integrity. For rocker arms, selecting the wrong drill or end mill can result in burr formation or micro-cracks.

Key considerations include:

-

Tool coating selection

-

Helix angle optimization

-

Chip evacuation efficiency

CNCRUSH’s CNC machining service integrates tooling strategies tailored for automotive and automotion environments where repeatability matters more than speed alone.

CNC Milling and Drilling Process Optimization

Optimizing CNC Manufacturing is not about pushing machines harder — it’s about machining smarter.

Process optimization includes:

-

Pre-milling reference faces

-

Controlled drilling sequences

-

Post-machining stress relief

These methods significantly improve consistency in CNC Milled parts, especially when rocker arms are produced in medium to high volumes.

CNC Milling Quality Control for Rocker Arms

Quality control transforms CNC Milling from a machining task into a manufacturing system.

Our CNC machining service applies:

-

In-process probing

-

Post-machining CMM inspection

-

Statistical process control

This ensures rocker arms meet functional and dimensional requirements across automotive, machine building and automotion sectors.

CNC Milling and Drilling vs Traditional Machining

Traditional machining lacks the consistency required for modern rocker arm production. CNC Milling eliminates human variability and ensures repeatable outcomes.

| Process Type | Accuracy | Repeatability | Suitability for Rocker Arms |

|---|---|---|---|

| Manual Machining | Low | Inconsistent | Poor |

| Semi-Automatic | Medium | Limited | Moderate |

| CNC Milling | High | Excellent | Ideal |

CNC Milling Cost Efficiency Analysis

Precision does not mean excessive cost when CNC Milling is applied correctly.

| Factor | CNC Milling Impact |

|---|---|

| Tool Life | Extended |

| Scrap Rate | Reduced |

| Labor Cost | Optimized |

| Overall ROI | Strong |

Our CNC machining service balances quality and cost efficiency, enabling global customers to scale production with confidence.

CNC Milling and Drilling: Why CNCRUSH Is Your Reliable Partner

With 12 years of experience, CNCRUSH has built a reputation as a reliable China-based CNC machining service provider.

We specialize in:

-

CNC Milled parts

-

CNC Turned parts

-

Automotive and automotion components

-

Machine building solutions

Our team understands that rocker arms are not just parts — they are performance-critical components.

FAQ: CNC Milling for Rocker Arms

Q1: Why is CNC Machining critical for rocker arms?

CNC Milling ensures dimensional accuracy, consistent hole alignment, and superior surface finish required for high-load applications.

Q2: What materials are commonly used?

Aluminum alloys and alloy steels are widely used depending on automotive performance requirements.

Q3: Can CNC Machining reduce failure risk?

Yes. Proper tool paths and stress management significantly reduce fatigue-related failures.

Q4: Does CNCRUSH support custom designs?

Absolutely. Our CNC machining service supports fully customized CNC Milled parts and CNC Turned parts.

Final Thoughts: CNC Milling That Builds Confidence

CNC Machining is more than a manufacturing process — it is a commitment to precision, reliability, and performance. When rocker arms fail, the consequences are negative and costly. When they are machined correctly, they become invisible heroes of automotive and automotion systems.

If you are looking for a professional CNC machining service, CNCRUSH is ready to support your next project with expertise, consistency, and confidence built over 12 years of real-world manufacturing experience.