CNC Milling plays a critical role in modern automotive, machine building, and automotion industries, especially in the production of cylinder blocks. Cylinder blocks are the heart of an engine, requiring high precision and durability to withstand heat, pressure, and mechanical stress. Improper machining can lead to performance loss, increased wear, and reduced engine longevity. In this article, we’ll explore 12 powerful CNC milling and boring techniques for cylinder blocks, providing deep insights, practical applications, and guidance for manufacturers. At CNCRUSH, we specialize in professional CNC machining service with over 12 years of experience, producing high-quality CNC Milled parts and CNC Turned parts for clients worldwide.

1. Importance of Precision CNC Milling in Cylinder Blocks

Cylinder blocks require tight tolerances and smooth surfaces to ensure optimal engine performance. CNC milling provides:

-

Consistent flatness of deck surfaces

-

Accurate positioning of cylinder bores

-

Reduction of surface imperfections

Analysis: Even minor deviations in cylinder block surfaces can cause gasket leaks or uneven piston motion. At CNCRUSH, we use high-precision CNC Milled parts and CNC Turned parts to achieve repeatable accuracy, enhancing engine efficiency and reliability.

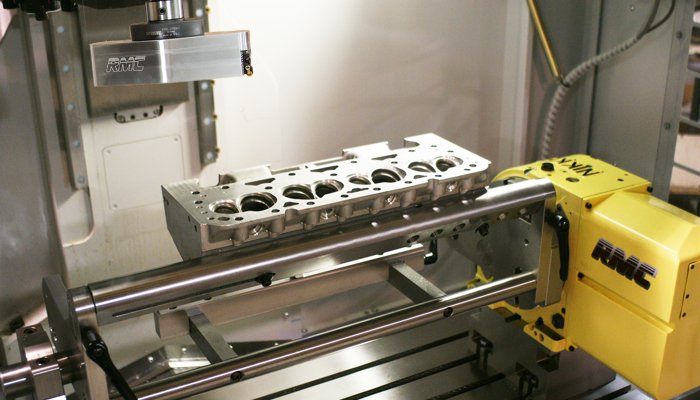

2. Advanced CNC Boring for Engine Cylinders

Boring is critical for achieving precise cylinder diameters and surface finishes. CNC boring allows:

-

Uniform cylinder dimensions across all bores

-

Improved piston fit and reduced oil consumption

-

Minimized vibration and engine noise

CNCRUSH Advantage: Our CNC machining service ensures every cylinder is bored to exact specifications, providing reliable performance for automotive and machine-building applications.

3. Managing Thermal Expansion During Machining

High-speed milling generates heat, causing thermal expansion that can distort cylinder blocks. Effective techniques include:

| Issue | Impact | CNC Solution |

|---|---|---|

| Thermal warping | Misaligned bores | Controlled coolant flow and material-specific feeds |

| Uneven stress | Cracks or distortions | Stepwise milling and boring passes |

| Residual stress | Reduced lifespan | Post-machining stress-relief treatments |

CNCRUSH applies these methods to all CNC Milled parts and CNC Turned parts, ensuring dimensional stability under extreme conditions.

4. Optimizing Surface Finish for Cylinder Longevity

Surface finish affects wear, friction, and heat dissipation. CNC milling and boring optimize:

-

Deck surface flatness

-

Cylinder wall smoothness

-

Critical contact points for pistons and bearings

Proper finishing enhances engine life, and CNCRUSH delivers CNC Milled parts and CNC Turned parts with superior surface quality.

5. Multi-Axis CNC Machining for Complex Geometries

Cylinder blocks contain water jackets, oil galleries, and intricate bore patterns. Multi-axis CNC machines allow:

-

Complex pocket milling

-

Accurate positioning of threaded holes

-

Reduction of rework and scrap

Analysis: CNCRUSH’s 3-axis, 4-axis, and 5-axis CNC machines produce complex cylinder blocks efficiently, guaranteeing precision in CNC Milled parts and CNC Turned parts for automotion projects.

6. Tool Selection and Maintenance

Correct tooling is essential for both milling and boring. Improper tools can cause:

-

Inconsistent bore diameter

-

Surface scratches

-

Excessive wear

CNCRUSH uses carbide and coated tools optimized for CNC Milled parts and CNC Turned parts. Predictive maintenance ensures minimal downtime and high-quality output.

7. Chip Evacuation and Coolant Techniques

Effective chip removal prevents damage to bores and block surfaces. Techniques include:

-

High-pressure coolant to remove chips

-

Optimized tool paths to minimize accumulation

-

Vacuum extraction systems for deep pockets

Efficient chip management reduces post-processing time and ensures the longevity of both CNC Milled parts and CNC Turned parts.

8. Fixturing and Workholding Challenges

Cylinder blocks have uneven shapes and delicate sections. Poor fixturing can lead to:

-

Vibration and chatter

-

Misaligned bores

-

Surface damage

CNCRUSH uses custom modular fixtures to securely hold blocks, ensuring stable and precise machining of CNC Milled parts and CNC Turned parts.

9. Maintaining Tight Tolerances Across Batches

Consistency is critical, especially in high-volume production. Challenges include:

| Tolerance Issue | Effect | Solution |

|---|---|---|

| Cylinder bore variation | Piston misfit | High-precision CNC boring and turning |

| Deck surface deviation | Gasket leaks | Automated measurement and correction |

| Thread misalignment | Assembly failure | Precision threading using CNC |

CNCRUSH ensures every CNC Milled part and CNC Turned part meets strict tolerances for reliable automotive performance.

10. Integrating Digital Measurement and Quality Control

Digital inspection and CMM (Coordinate Measuring Machine) integration allow:

-

Real-time monitoring of bore diameters

-

Verification of critical surfaces

-

Early detection of errors to reduce scrap

At CNCRUSH, we combine CNC milling service with rigorous inspection, ensuring CNC Milled parts and CNC Turned parts are consistently high-quality.

11. Post-Machining Treatments to Enhance Durability

After milling and boring, cylinder blocks often require:

-

Stress-relief heat treatments

-

Surface coatings or honing for reduced friction

-

Quality validation for long-term performance

These steps help extend engine lifespan, and CNCRUSH applies them to all CNC Milled parts and CNC Turned parts.

12. CNC Milling Service for Automotive, Machine Building, and Automotion Applications

High-performance cylinder blocks demand precise machining. CNCRUSH’s services include:

-

CNC Milled parts for engine decks, water jackets, and mounting surfaces

-

CNC Turned parts for cylinders, shafts, and threaded components

-

Reliable production for automotive, machine building, and automotion industries

Our 12 years of expertise ensures clients receive components that meet strict quality, precision, and performance standards.

FAQ: CNC Milling and Boring for Cylinder Blocks

Q1: What is the difference between CNC milling and boring?

A: Milling shapes surfaces, removes material, and creates flat or contoured areas, while boring enlarges and finishes pre-existing holes to precise diameters.

Q2: Can CNCRUSH handle high-volume cylinder block production?

A: Yes, with advanced multi-axis machines and experienced operators, we provide high-volume CNC Milled parts and CNC Turned parts with consistent quality.

Q3: How do you control thermal expansion during machining?

A: By using proper coolant, stepwise passes, and stress-relief treatments, CNCRUSH maintains dimensional accuracy.

Q4: What materials are commonly machined for cylinder blocks?

A: Aluminum alloys, cast iron, and specialty alloys. CNCRUSH can handle all of these with precision CNC machining service.

By mastering these CNC milling and boring techniques, manufacturers can improve engine performance, reliability, and longevity. CNCRUSH delivers professional CNC machining service, producing high-quality CNC Milled parts and CNC Turned parts tailored to automotive, machine building, and automotion applications.