The performance and efficiency of CNC milling depend heavily on the optimization of feed rates and spindle speeds. A well-optimized feed rate enhances surface quality, improves tool life, and minimizes machining cycle times. In this article, we’ll dive into advanced techniques for optimizing feed rates specifically for CNC milling and other CNC machining processes like turning. We will also examine various materials and cutting conditions, using insights from a range of technical sources. Finally, we will tailor the content to highlight the CNC machining services offered by CNCRUSH, a precision CNC machining provider based in China, specializing in CNC Milled parts and CNC Turned parts for industries like automotive, machine building, and automation.

Understanding CNC Milling and Feed Rate Optimization

CNC milling involves using a rotating cutting tool to remove material from a workpiece. Feed rate, along with spindle speed, plays a critical role in determining the efficiency, quality, and cost of production. Feed rate refers to the distance that the cutting tool moves in one spindle revolution. Properly optimizing this ensures smooth cuts, minimizes tool wear, and avoids thermal damage to the workpiece. By balancing feed rates and spindle speeds, manufacturers can ensure the best material removal rate without compromising the quality of parts.

Table of Contents

- What is Feed Rate in CNC Milling?

- Why Optimizing Feed Rates is Important for CNC Milling

- Calculating Optimal Feed Rates

- Impact of Material Properties on Feed Rates

- Effect of Tool Geometry on Feed Rates

- Advanced Feed Rate Optimization Techniques

- Avoiding Common Feed Rate Mistakes

- Automated Feed Rate Optimization Technologies

- Balancing Feed Rates for CNC Milled Parts vs. CNC Turned Parts

- How CNCRUSH Enhances CNC Machining Efficiency

1. What is Feed Rate in CNC Milling?

The feed rate is a crucial aspect of CNC machining and refers to the velocity at which the cutting tool moves against the workpiece. It is typically measured in inches per minute (IPM) or millimeters per minute (mm/min). In CNC milling, a higher feed rate allows for quicker material removal, but if set incorrectly, it can cause surface defects, tool damage, or even machine breakdowns.

2. Why Optimizing Feed Rates is Important for CNC Milling

Optimizing feed rates offers a number of benefits, including:

- Improved Surface Finish: A well-calculated feed rate can reduce imperfections like burrs, chipping, or rough textures.

- Increased Tool Life: When the feed rate is optimized, tools experience less wear and tear, reducing the cost and downtime associated with tool replacements.

- Higher Efficiency: Proper feed rate optimization decreases machining times while maintaining quality, which increases overall productivity.

This is particularly critical in industries such as automotive, machine building, and automation, where precision and efficiency are key.

3. Calculating Optimal Feed Rates

There are several factors that influence feed rate calculations:

| Factors | Description |

|---|---|

| Material Hardness | Harder materials require lower feed rates to avoid excessive tool wear. |

| Tool Material | The durability and sharpness of the cutting tool material affect how aggressively it can cut. |

| Spindle Speed | Feed rate must be balanced with spindle speed to avoid excessive heat and tool failure. |

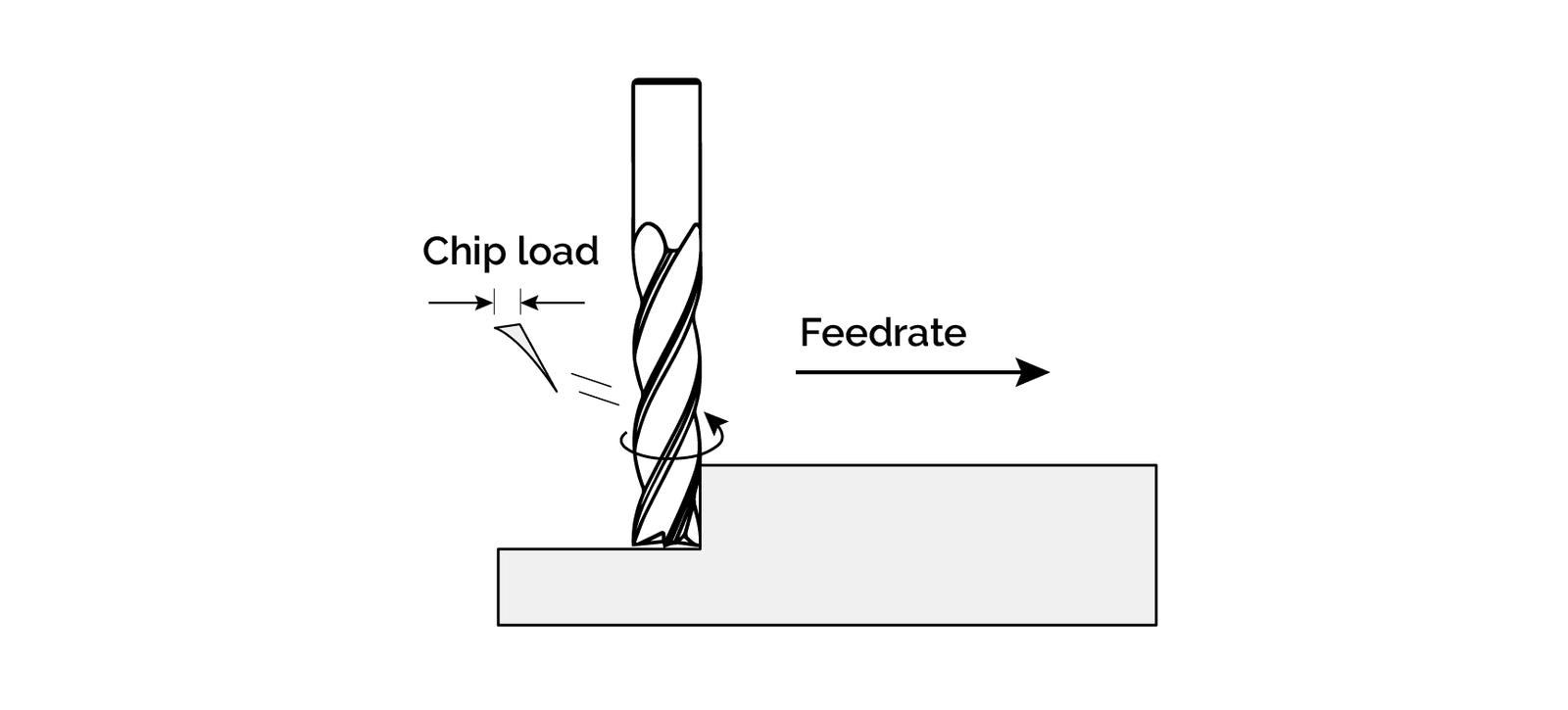

| Chip Load | This refers to the thickness of the material that each cutting edge removes. It’s calculated as: Chip Load = Feed Rate ÷ (Number of Flutes × RPM). |

Optimizing these factors together results in the best performance for CNC milling operations.

4. Impact of Material Properties on Feed Rates

Material properties are critical to determining the right feed rate for a given machining operation. For example:

- Metals like steel and aluminum: Require careful consideration because they generate significant heat during cutting. For CNC machining steel, lower feed rates paired with moderate spindle speeds prevent overheating.

- Plastics: Feed rates can be higher due to lower hardness and cutting resistance, but careful control is needed to avoid melting.

By understanding the material’s properties, manufacturers can make better decisions to balance productivity and quality.

5. Effect of Tool Geometry on Feed Rates

The number of flutes on a cutting tool, its coating, and the tool’s geometry also play a pivotal role in determining optimal feed rates. Tools with more flutes can handle higher feed rates since more cutting edges engage the workpiece simultaneously. However, more flutes also mean the tool needs to clear chips faster to avoid overheating. Additionally, tools designed for specific materials (e.g., carbide tools for hard metals) can tolerate higher feed rates and spindle speeds without wearing out prematurely.

6. Advanced Feed Rate Optimization Techniques

To maximize productivity, advanced methods like constant chip thickness are often used. This method ensures that the tool removes an equal amount of material with each pass, preventing tool overloads and uneven surfaces.

Automated software solutions like Vericut Force, mentioned in many CNC machining optimization resources, allow real-time analysis of cutting forces, spindle power, and torque levels to adjust feed rates dynamically throughout a machining process. This enables CAM programmers to ensure that tools are always operating at their peak efficiency.

| Scenario | Feed Rate Adjustment |

|---|---|

| High cutting forces | Decrease feed rate to prevent tool damage. |

| Excessive vibration | Lower feed rate and increase tool engagement for a smoother operation. |

| Underutilized tool | Increase feed rate to maximize material removal rates. |

7. Avoiding Common Feed Rate Mistakes

Incorrect feed rates can lead to a number of problems, including:

- Tool Breakage: Occurs when the feed rate is too high, causing excessive cutting forces on the tool.

- Poor Surface Finish: A feed rate that’s too low can result in chattering, which affects the final quality of the part.

- Thermal Damage: Excessive feed rates can generate heat, causing material melting (particularly in plastics) or tool degradation in metals like aluminum.

8. Automated Feed Rate Optimization Technologies

Recent advances in CAM software, like Force optimization modules, make it possible to automate feed rate optimization. These tools dynamically adjust feed rates based on cutting conditions, spindle load, and chip thickness, reducing human error and improving overall machining performance. Companies like Sandvik Coromant have demonstrated significant reductions in tool wear and cycle time using these tools in aerospace and automotive machining projects.

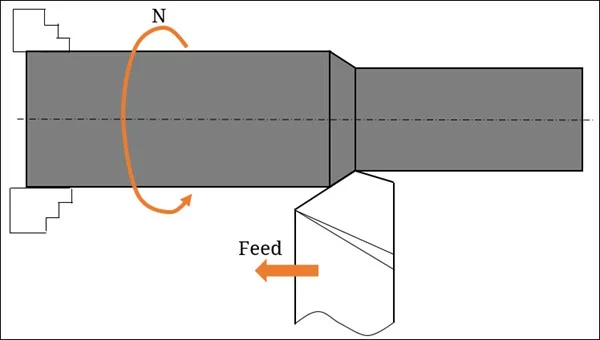

9. Balancing Feed Rates for CNC Milling Parts vs. CNC Turned Parts

Feed rates are equally critical in CNC turning operations, where the workpiece rotates rather than the tool. However, the principles remain similar—matching feed rates to material type, tool geometry, and spindle speed. For precision parts, especially in automotive and automation, where tolerances are tight, optimized feed rates ensure accuracy and high-quality surface finishes.

10. How CNCRUSH Enhances CNC Milling Efficiency

At CNCRUSH, with over 12 years of experience in CNC machining services, we specialize in CNC Milling parts and CNC Turning parts for clients in industries such as automotive, machine building, and automation. We apply cutting-edge feed rate optimization techniques to ensure the highest levels of precision and efficiency. Whether you need high-volume production or prototype development, we offer solutions that meet strict tolerances and deliver consistent results.

By integrating advanced CAM software and optimizing feed rates, CNCRUSH has consistently improved part quality while reducing cycle times and tool wear. This has made us a trusted partner for companies around the world looking for precision CNC machining and custom CNC solutions.

FAQ on CNC Milling Feed Rates

Q1: How do I determine the best feed rate for a new material?

A1: Start by referring to feed rate guidelines provided by tool manufacturers, then perform test cuts, adjusting the feed rate based on chip load and surface finish quality.

Q2: Can I optimize feed rates automatically?

A2: Yes, many modern CAM systems offer automated feed rate optimization tools like Vericut, which analyze the machining process and adjust feed rates in real time.

Q3: How does spindle speed affect feed rate optimization?

A3: Spindle speed and feed rate work together. Increasing the spindle speed without adjusting the feed rate can cause overheating, while a slow spindle speed with a fast feed rate can lead to poor surface finishes and tool damage.

This structured approach to feed rate optimization, when applied in CNC milling, ensures not just optimal tool performance but also cost savings and improved part quality—a must for industries like automotive, machine building, and automation. For expert CNC machining services, trust CNCRUSH to deliver precision and efficiency in every project.