Precision CNC Machining has become a cornerstone of modern automotive manufacturing, driving advances in both the production process and the performance of vehicles. From engine components to custom parts, the use of CNC milling and turning in the automotive industry enhances precision, repeatability, and efficiency. As demand for high-performance cars increases, so does the need for reliable, high-quality machining solutions.

At CNCRUSH, we specialize in providing expert CNC machining services to the automotive industry. With 12 years of experience, our facility in China is equipped with cutting-edge technology to deliver precision CNC Milled parts and CNC Turned parts. We cater to a range of industries, including automotive, machine building, and automation, ensuring that each part meets strict quality and performance standards.

1. Introduction to Precision CNC Machining in the Automotive Industry

The automotive sector is one of the most demanding industries, requiring high precision and tight tolerances for critical components. Precision CNC machining plays an essential role in producing parts that ensure the safety, performance, and reliability of vehicles. From engine blocks to drive axles, CNC machining is crucial for the development and mass production of automotive parts.

Automotive manufacturers increasingly rely on CNC machining services to produce complex components quickly and accurately, reducing lead times and improving overall efficiency.

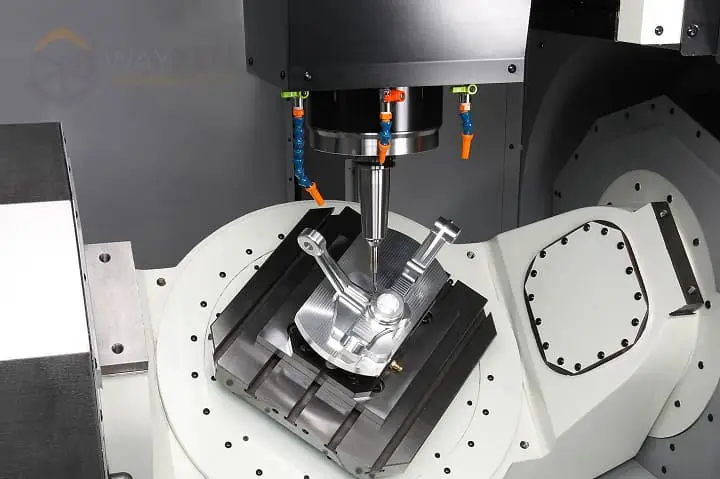

2. CNC Machining for Engine Components: Ensuring Performance and Durability

Engine components such as cylinder heads, crankshafts, and pistons require extreme precision due to their role in vehicle performance. CNC milling and CNC turning are used to create these parts with tight tolerances and excellent surface finishes. Materials like aluminum and steel are commonly used, as they offer strength while keeping the components lightweight.

Solution: At CNCRUSH, we offer precision CNC machining for engine components, ensuring that each part is manufactured to exact specifications. Our advanced machines and experienced engineers ensure high durability and consistent quality across production runs.

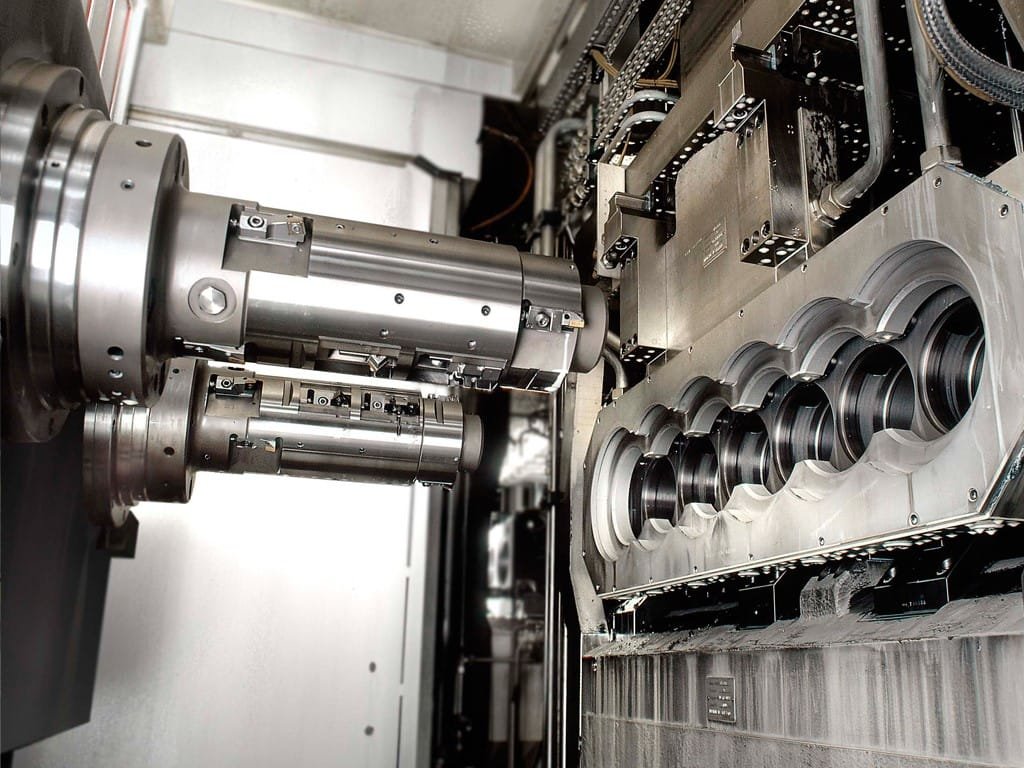

3. Gearbox and Transmission Systems: Precision and Efficiency

The gearbox is a critical part of any vehicle’s transmission system. CNC machining helps produce gears with the accuracy required to ensure smooth transitions and minimize wear over time. Using CNC milling and CNC turning, we can manufacture intricate gears and shafts that contribute to the vehicle’s overall performance and efficiency.

| Component | Machining Method | Material |

|---|---|---|

| Cylinder Head | CNC Milling and Turning | Aluminum, Steel |

| Crankshaft | CNC Turning | Steel, Cast Iron |

| Gearbox Components | CNC Milling and Drilling | Alloy Steel, Titanium |

4. Custom Parts for Automotive Prototyping and Restoration

CNC machining excels in producing custom and rare parts, especially for prototype development and vehicle restoration. Classic car enthusiasts often require parts that are no longer available from manufacturers. CNC machining allows for reverse engineering of these components, ensuring an accurate fit and function.

At CNCRUSH, we specialize in creating one-off parts for classic cars and prototyping new designs for automotive manufacturers. Our custom CNC solutions ensure that parts are recreated or developed with high precision.

5. Interior and Exterior Panels: Lightweight and Durable Solutions

As the automotive industry shifts toward lightweight materials to improve fuel efficiency, CNC machining is increasingly used to produce interior and exterior panels. Materials like plastic composites and lightweight metals are machined with precision to ensure durability while reducing overall vehicle weight.

Our CNC Milled parts for interior components, such as dashboard frames and control panels, provide seamless integration into vehicle designs, maintaining both aesthetics and functionality.

6. Advantages of Precision CNC Machining for Automotive Manufacturing

Speed and Automation

CNC machining offers faster production times than traditional methods, thanks to its automated nature. This allows for high-volume production without sacrificing quality. At CNCRUSH, our automated CNC systems ensure rapid turnaround times and consistent quality across large production runs.

Repeatability and Precision

One of the key advantages of CNC machining is its ability to produce identical parts with high precision. This repeatability is essential for automotive manufacturing, where even the smallest deviation can affect vehicle performance.

Customization and Flexibility

CNC machining allows for the quick adjustment of production setups, enabling manufacturers to switch between different designs with minimal downtime. This flexibility is crucial in the automotive industry, where custom parts and new designs are regularly introduced.

7. Challenges in Precision CNC Machining for Automotive Applications

While CNC machining offers many benefits, there are challenges in producing automotive components, including:

- Complex Geometries: Many automotive parts, such as turbine blades and intake manifolds, have intricate shapes that require advanced CNC capabilities.

- Material Hardness: Components like crankshafts and pistons are made from hardened materials, which can be difficult to machine without causing tool wear or compromising quality.

- Tight Tolerances: Parts like engine components and transmission gears must meet extremely tight tolerances to function correctly.

Solution: CNCRUSH’s experienced team and state-of-the-art machinery are equipped to handle these challenges, ensuring precision and reliability in every part we produce.

8. CNC Machining for Automotive Prototyping: Speeding Up Development Cycles

Rapid prototyping is essential for automotive manufacturers to test and refine new designs. CNC machining allows for the quick production of functional prototypes that can be tested in real-world conditions. This helps manufacturers identify design flaws early in the development process, reducing costly rework later on.

At CNCRUSH, we provide rapid CNC prototyping services that help automotive companies bring their innovations to market faster.

9. CNC Machining and Automation: The Future of Automotive Manufacturing

The automotive industry is embracing automation and Industry 4.0 to improve efficiency and reduce costs. CNC machining plays a key role in this transformation, with machines that can operate autonomously and produce high-precision parts with minimal human intervention.

At CNCRUSH, we integrate the latest automation technologies into our CNC processes, ensuring that our clients receive high-quality parts on time and within budget.

10. Why Choose CNCRUSH for Your Automotive Precision CNC Machining Needs?

With over 12 years of experience in Precision CNC Machiningservices, CNCRUSH is a trusted partner for automotive manufacturers. We offer:

- Expertise: Skilled engineers and advanced CNC technology to produce high-precision parts.

- Flexibility: Custom solutions for both large production runs and small prototypes.

- Quality Assurance: Rigorous inspection processes to ensure every part meets the highest standards.

- Competitive Pricing: Affordable Precision CNC Machining without compromising on quality.

FAQ

Q1. What automotive parts can be made using Precision CNC Machining?

CNC machining is used to create a wide range of automotive components, including engine blocks, transmission gears, interior panels, and custom parts for vintage car restoration.

Q2. How does Precision CNC Machining benefit automotive prototyping?

CNC machining enables rapid prototyping, allowing manufacturers to produce high-quality functional prototypes that can be tested and refined before moving into mass production.

Q3. Why is Precision CNC Machining preferred for high-precision automotive parts?

CNC machining offers tight tolerances and repeatability, which are essential for the performance and safety of critical automotive components such as engine parts and transmission systems.

For top-tier CNC Milled parts and CNC Turned parts, trust CNCRUSH to deliver precision, quality, and reliability. Contact us today to learn more about our CNC machining services for the automotive sector!

zet casino test

5cad0e4