CNC Machining enables the precision manufacturing of complex turbocharger housings by controlling geometry, surface quality, and dimensional accuracy for high-performance automotive applications. CNC Machining is the decisive technology behind modern turbocharger housing manufacturing, where complex internal geometry, extreme rotational speed, and thermal-mechanical stress converge into one of the most demanding challenges in automotive production.

Introduction: Why Turbocharger Housings Are a CNC Machining Challenge

CNC Machining sits at the core of turbocharger housing production because few components combine such complex shapes, tight tolerances, and unforgiving performance conditions. Turbocharger housings must guide airflow efficiently, withstand high temperatures, and maintain dimensional stability at extreme rotational speeds.

From industry analysis and manufacturing studies, one negative reality stands out clearly:

most turbocharger failures originate from geometric inaccuracies, surface defects, or machining-induced stress rather than material selection alone.

This article distills those insights into 12 proven CNC Machining strategies, combining advanced multi-axis machining knowledge with real-world production experience. It is written for engineers, procurement teams, and manufacturers in automotive, machine building and automotion industries who demand reliability instead of costly rework.

1: CNC Machining and the Geometric Complexity of Turbocharger Housings

Turbocharger housings feature volutes, spiral flow paths, thin walls, and intersecting curves that are nearly impossible to produce accurately using conventional methods alone.

With CNC Machining, especially multi-axis systems, manufacturers gain:

-

Continuous tool engagement along curved surfaces

-

Precise control of airflow geometry

-

Reduced mismatch between compressor and turbine sections

This is where professional cnc machining service providers create value—not by cutting metal faster, but by controlling geometry with confidence.

2: CNC Machining Service and 5-Axis Capability for Turbocharger Accuracy

Turbocharger housings benefit enormously from 5-axis machining due to their undercuts and internal contours.

A high-level CNC Machining service using 5-axis systems can:

-

Reduce setups and alignment errors

-

Improve surface continuity

-

Achieve tighter tolerances on complex shapes

This capability directly translates into higher efficiency and reduced vibration during turbocharger operation—critical for high-performance automotive applications.

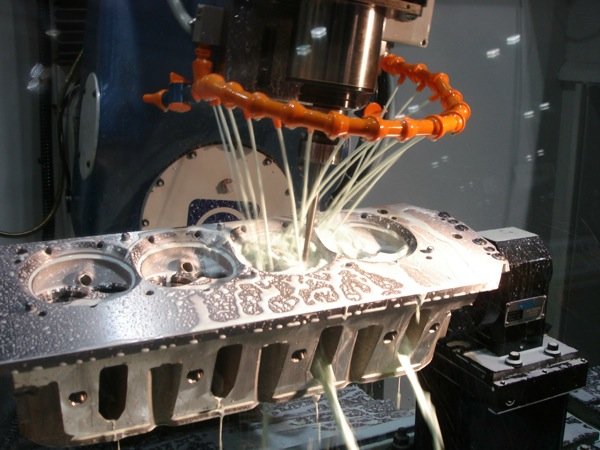

3: CNC Milled Parts and Internal Flow Path Optimization

Internal airflow efficiency defines turbocharger performance. Even small geometric deviations create turbulence and pressure loss.

Through CNC Milled parts, manufacturers can:

-

Smooth internal transitions

-

Maintain consistent cross-sections

-

Optimize volute expansion ratios

This level of precision machining leads to positive performance gains, making CNC Machining essential rather than optional.

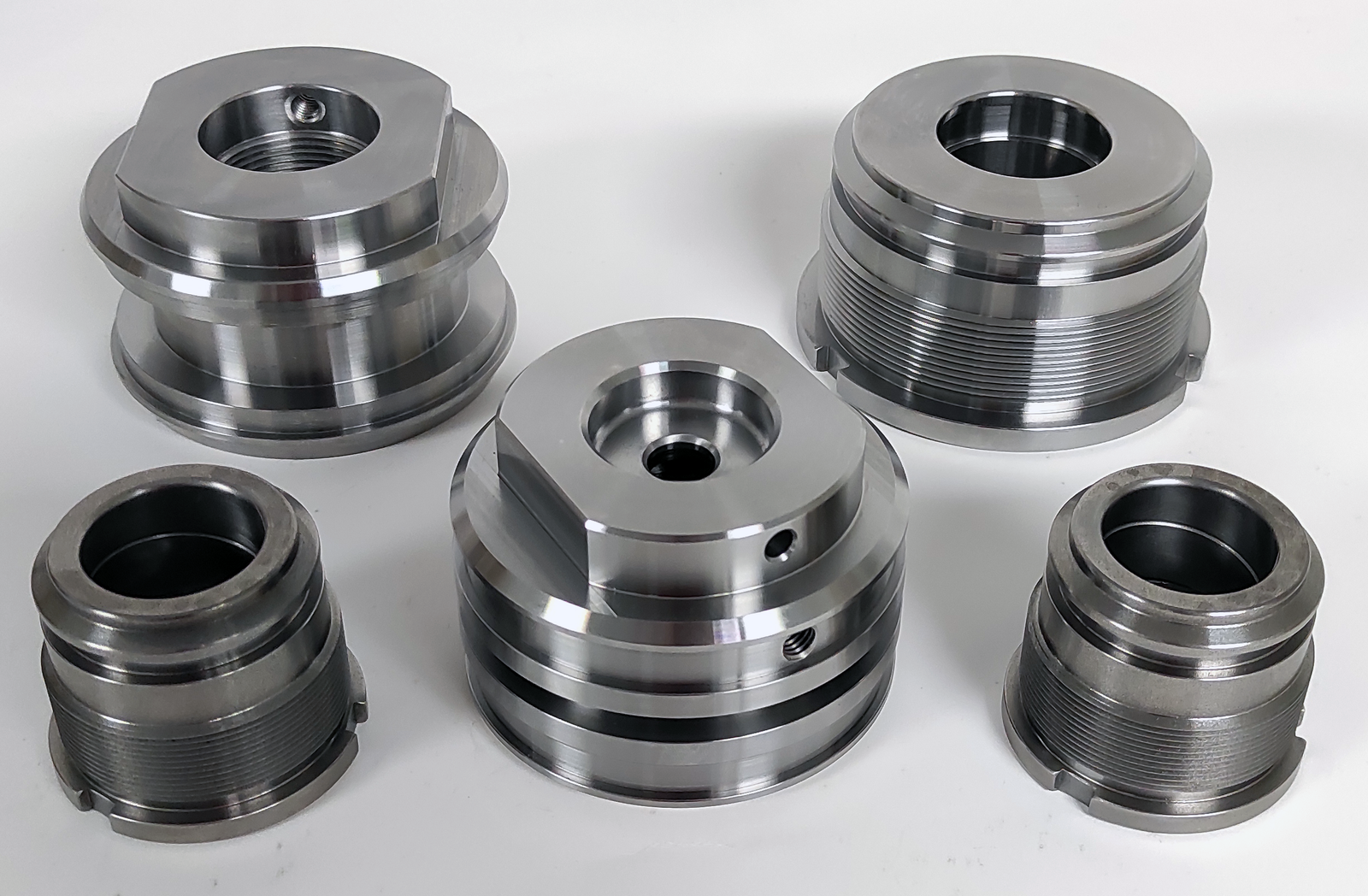

4: CNC Turned Parts for Turbocharger Interfaces and Bearing Seats

While housings are complex, their interfaces must be perfectly concentric and stable.

Precision CNC Turned parts are used for:

-

Bearing housings

-

Mounting flanges

-

Seal interfaces

A poor turning operation introduces imbalance, leading to catastrophic failure at high RPM. Reliable CNC precision Machining eliminates this risk.

5: CNC Machining Service Material Control in Turbocharger Housings

Turbocharger housings are commonly machined from aluminum alloys, stainless steel, or special cast iron grades.

| Material | Machinability | Thermal Stability | Typical Use |

|---|---|---|---|

| Aluminum Alloy | Excellent | Medium | Compressor housings |

| Stainless Steel | Difficult | High | Performance turbines |

| Cast Iron | Moderate | Very High | OEM turbine housings |

A skilled cnc precision machining service adapts cutting tools, feeds, and cooling strategies to each material’s behavior under heat.

6: CNC Machining and Thermal Distortion Control

Thermal distortion during machining is a frustrating but avoidable problem.

Professional CNC Machining controls distortion through:

-

Balanced machining sequences

-

Adaptive roughing strategies

-

Stress-relief machining passes

These methods ensure turbocharger housings remain dimensionally stable during real-world operation.

7: CNC Milled Parts Surface Finish and Turbo Efficiency

Surface roughness directly affects airflow efficiency.

| Surface Roughness (Ra) | Airflow Efficiency | Risk Level |

|---|---|---|

| >3.2 µm | Poor | High |

| 1.6–3.2 µm | Acceptable | Medium |

| <1.6 µm | Excellent | Low |

High-quality CNC Milled parts achieve smoother surfaces, reducing turbulence and improving compressor response.

8: CNC Turned Parts and Dimensional Stability at High RPM

Turbochargers operate at extreme speeds. Any imbalance is dangerous.

Precision CNC Turned parts ensure:

-

Concentricity within microns

-

Stable bearing alignment

-

Reduced vibration

This level of precision CNC Machining is non-negotiable in automotion systems.

9: CNC Machining Service Quality Control for Turbocharger Reliability

A strong quality control system separates reliable suppliers from risky ones.

Effective CNC precision Machining service inspection includes:

-

CMM dimensional verification

-

Surface roughness measurement

-

Geometric profile inspection

At CNCRUSH, every CNC Milled part and CNC Turned part is inspected to ensure repeatability across production batches.

10: CNC Machining and Hybrid Manufacturing Strategies

Many manufacturers combine casting with CNC precision Machining for optimal results.

| Process | Shape Complexity | Precision | Cost Efficiency |

|---|---|---|---|

| Casting Only | High | Low | Medium |

| CNC Machining Only | Medium | Very High | Low |

| Hybrid Approach | Very High | High | High |

Hybrid strategies allow cnc precision machining service providers to correct casting imperfections and achieve final precision.

11: CNC Machining Service for Automotive Turbocharger Production Scalability

Scalability is often overlooked. Prototypes are easy—production is hard.

A reliable CNC precision Machining service supports:

-

Consistent repeatability

-

Tool life optimization

-

Stable lead times

This is critical for automotive, machine building and automotion manufacturers scaling production.

12: CNC Machining Experience as a Competitive Advantage

Experience matters. Poor machining decisions create expensive failures and unhappy customers.

CNCRUSH, based in China, offers:

-

12 years of professional CNC Machining experience

-

High-quality CNC Milled parts

-

Precision CNC Turned parts

-

Trusted service for global customers

We do not just machine parts—we solve manufacturing problems.

Why Choose CNCRUSH for Turbocharger Housing CNC precision Machining

CNCRUSH | High-Quality CNC Milling & Turning Solutions delivers precision, consistency, and confidence.

We specialize in:

-

Professional cnc machining service

-

Aluminum, steel, and plastic machining

-

Turbocharger components

-

Automotive and industrial applications

If you are looking for a CNC Machining partner who understands complex geometry and real-world performance demands, CNCRUSH is ready to support your project.

Frequently Asked Questions (FAQ)

Q1: Why is CNC precision Machining essential for turbocharger housings?

CNC Machining provides the accuracy, surface quality, and geometric control required for high-speed airflow and durability.

Q2: Are CNC Milled parts better than cast parts?

CNC Milled parts offer superior dimensional accuracy and surface finish, especially for internal flow paths.

Q3: What role do CNC Turned parts play in turbochargers?

They ensure concentric bearing seats and stable interfaces that prevent vibration and failure.

Q4: Can aluminum turbo housings handle high temperatures?

Yes, when properly designed and machined using professional CNC precision Machining processes.

Q5: What industries benefit most from this machining approach?

Automotive, machine building and automotion industries benefit the most.

Final Conclusion: CNC Precision Machining Turns Complexity into Competitive Strength

Turbocharger housings represent one of the most demanding and unforgiving machining challenges. Success depends not on luck, but on precision, experience, and engineering discipline.

CNC Machining transforms complex shapes into reliable performance.

With CNCRUSH, complexity becomes confidence.

Outstanding post, I conceive website owners should acquire a lot from this weblog its rattling user friendly. So much excellent info on here :D.