CNC Machining is at the heart of producing high-quality crankcase covers that meet the demanding tolerances of automotive, machine building, and automotion applications. Precision, reliability, and durability are non-negotiable, and the choice of CNC machining techniques directly influences the performance of engine components. At CNCRUSH, a professional CNC machining service based in China with over 12 years of experience, we specialize in producing superior CNC Milled parts and CNC Turned parts for global clients seeking high-precision solutions.

In this article, we will explore 10 advanced CNC machining techniques for crankcase covers, their applications, and how our expertise ensures consistent quality, minimal defects, and optimal performance.

CNC Machining Service: Why Precision Matters for Crankcase Covers

The crankcase cover is a critical component in any internal combustion engine. It houses bearings, seals, and various channels that facilitate lubrication and cooling. Small deviations in dimension or surface finish can compromise engine performance, leading to leaks, premature wear, or even catastrophic failures.

A professional CNC machining service ensures that each crankcase cover adheres to exact specifications. At CNCRUSH, we utilize advanced 5-axis CNC machines that maintain tolerances within microns. Our precision-focused processes make our clients in automotive, machine building, and automotion confident that every part will fit perfectly and operate reliably under high stress.

Key considerations for precision CNC machining service:

-

Dimensional accuracy and tight tolerances

-

Consistent repeatability for batch production

-

Surface finish quality to reduce friction and wear

CNC Milled Parts: Material Selection for Optimal Performance

Choosing the right material is the first step in producing high-quality CNC Milled parts for crankcase covers. Common materials include aluminum alloys like 6063-T6, cast iron, and various grades of steel. Each material presents unique machining challenges and benefits.

-

Aluminum 6063-T6: Lightweight, corrosion-resistant, and easy to machine; ideal for automotive crankcase covers requiring weight reduction.

-

Cast Iron: Excellent vibration damping, ideal for heavy-duty engines but harder to machine.

-

Steel Alloys: High strength and wear resistance, suitable for high-stress industrial applications.

Our CNC machining service team evaluates material selection based on strength, thermal properties, and compatibility with surface finishing processes. Optimizing material choice ensures durability and performance of every CNC Milled part.

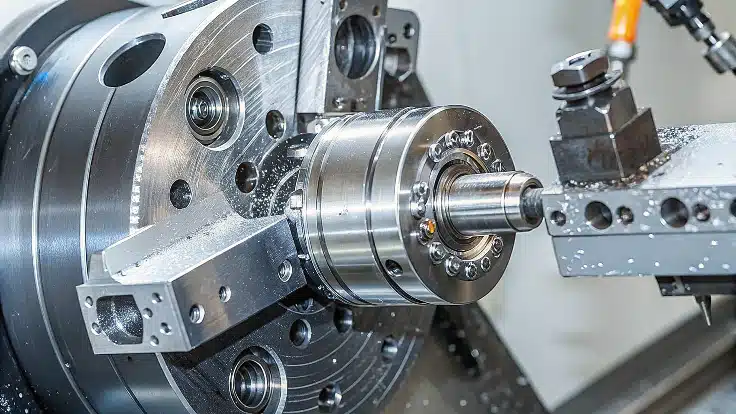

CNC Turned Parts: Achieving Perfect Cylindrical Features

Crankcase covers often require precise cylindrical bores and shafts. This is where CNC Turned parts excel. Turning operations allow for high accuracy in diameters and concentricity, ensuring perfect alignment of engine components.

At CNCRUSH, our turning operations are complemented by in-process inspection using laser measurement and CMM systems. This guarantees that every shaft hole, bearing journal, or plug is within specified tolerances, reducing rework and enhancing engine reliability.

5 Critical Machining Techniques to Enhance Crankcase Strength

Achieving a durable crankcase cover involves combining several CNC machining service techniques:

-

Face Milling: Ensures flatness of mating surfaces.

-

Peripheral Milling: Creates precise contours and profiles.

-

Drilling and Boring: Produces accurate holes for fasteners and bearings.

-

Threading and Tapping: Integrates secure mounting points.

-

Deburring and Chamfering: Eliminates sharp edges and stress concentrators.

These techniques collectively enhance the structural integrity and longevity of the crankcase cover, preventing leaks and mechanical failures in high-performance applications.

Surface Finishing Techniques in CNC Machining Service

Surface finish significantly impacts the performance of crankcase covers. Poor finishes can lead to oil leaks, increased wear, and premature engine failure. Our CNC machining service includes advanced finishing techniques for both CNC Milled parts and CNC Turned parts:

-

Polishing and Deburring: Smooth surfaces for sealing and assembly.

-

Anodizing Aluminum: Provides corrosion resistance and enhances durability.

-

Chromium or Nickel Plating: Adds wear resistance for steel components.

Table 1: Surface Finish Recommendations for Crankcase Covers

| Material | Recommended Finish | Surface Roughness (Ra) |

|---|---|---|

| Aluminum 6063-T6 | Anodized & Polished | 0.8 – 1.6 µm |

| Steel Alloy | Nickel Plated & Polished | 0.4 – 0.8 µm |

| Cast Iron | Machined & Deburred | 1.6 – 3.2 µm |

Proper surface finishing not only enhances appearance but also improves reliability in demanding automotive and industrial environments.

Optimizing Automotive Crankcase Covers with CNC Milled Parts

Automotive crankcase covers require both CNC Milled parts precision and durability. CNC milling allows complex geometries, cooling channels, and mounting points to be accurately produced. At CNCRUSH, we leverage:

-

Multi-axis milling for intricate contours

-

Optimized tool paths to reduce residual stresses

-

Advanced coolant and chip removal systems for superior surface quality

By combining these techniques, our CNC Milled parts contribute to reduced engine weight, improved heat dissipation, and overall better performance.

Dimensional Accuracy and Tolerances in CNC Turned Parts

For features like bearing journals and cylindrical holes, CNC Turned parts must meet strict tolerances. Deviations of even 0.01 mm can result in misalignment or excessive wear.

Critical factors in CNC turned part precision:

-

Tool wear monitoring

-

Temperature control during machining

-

Precision fixturing and repeatable setups

At CNCRUSH, every batch of CNC Turned parts is inspected with CMM machines and laser measurement tools to ensure tolerances are met, which guarantees fit, function, and longevity.

Reducing Defects and Improving Yield: Advanced CNC Machining Service Practices

Even with advanced machinery, defects can occur. CNCRUSH employs quality-focused practices to reduce scrap and improve yield:

-

Real-time process monitoring

-

Tool path optimization to reduce vibrations

-

Automated inspection and feedback loops

By minimizing defects, we ensure consistent quality for CNC Milled parts and CNC Turned parts, delivering peace of mind for automotive, machine building, and automotion clients. Positive outcomes from these practices include faster production, reduced costs, and higher customer satisfaction.

Cost vs. Quality Analysis for Crankcase Production

Balancing cost and quality is critical in crankcase production. Below is a comparative analysis:

Table 2: CNC Milled vs CNC Turned Parts for Crankcase Covers

| Feature | CNC Milled Parts | CNC Turned Parts | Notes |

|---|---|---|---|

| Material Versatility | High | Medium | Milling handles complex shapes better |

| Dimensional Accuracy | ±0.01 mm | ±0.005 mm | Turning excels in cylindrical features |

| Lead Time | Moderate | Fast | Depends on batch size and complexity |

| Production Cost | Medium | Medium-High | Precision requirements influence cost |

| Surface Finish Quality | High | High | Depends on finishing techniques |

| Suitability for Automotive | Excellent | Excellent | Both are widely used |

This analysis helps manufacturers understand trade-offs and choose the right machining method for their needs.

Why Choose CNCRUSH for CNC Machining of Crankcase Covers

CNCRUSH is a trusted CNC machining service provider in China with 12 years of experience delivering high-precision CNC Milled parts and CNC Turned parts. Our dedication to quality, advanced machinery, and experienced engineers ensures:

-

Consistent dimensional accuracy

-

Superior surface finishes

-

Cost-effective production solutions

-

Timely delivery for automotive and industrial clients

If you are seeking professional CNC machining of crankcase covers or other components, CNCRUSH is your reliable partner. Our commitment to excellence guarantees that every part meets global standards for performance and reliability.

FAQ

Q1: What materials can CNCRUSH machine for crankcase covers?

A1: We work with aluminum alloys (6063-T6, 7075), steel alloys, and cast iron to produce durable CNC Milled parts and CNC Turned parts suitable for automotive and industrial applications.

Q2: How precise are your CNC Milled parts and CNC Turned parts?

A2: Our CNC Milled parts typically achieve ±0.01 mm tolerance, while CNC Turned parts achieve ±0.005 mm, ensuring high reliability in critical engine components.

Q3: Can CNCRUSH handle high-volume automotive orders?

A3: Yes, we have experience handling both small prototypes and high-volume production runs, delivering consistent quality and on-time shipments.

Conclusion

CNC Machining is the backbone of producing high-precision crankcase covers. By employing advanced CNC machining service techniques, optimizing material selection, ensuring tight tolerances, and performing superior finishing, manufacturers can produce durable, reliable, and high-performance components. CNCRUSH’s 12 years of experience in CNC Milled parts and CNC Turned parts production makes us the ideal partner for automotive, machine building, and automotion industries seeking precision, reliability, and value.