CNC Machining is a critical process in the production of high-precision timing sprockets and gear profiles for automotive, machine building, and automotion applications. Accurate gear profiles are essential to ensure proper meshing, smooth power transmission, and long-term durability. At CNCRUSH, a professional CNC machining service based in China with over 12 years of experience, we […]

Category Archives: CNCRUSH News

CNC Machining is at the heart of producing high-quality crankcase covers that meet the demanding tolerances of automotive, machine building, and automotion applications. Precision, reliability, and durability are non-negotiable, and the choice of CNC machining techniques directly influences the performance of engine components. At CNCRUSH, a professional CNC machining service based in China with over […]

CNC Milling is the foundation of precision manufacturing for rocker arms, combining high-accuracy milling and drilling processes to ensure strength, durability, and flawless motion in automotive, machine building and automotion applications. Overview: What the Original Sources Reveal About Rocker Arm Machining Across the referenced materials, one key message stands out clearly: rocker arms demand extreme […]

CNC Machining plays a crucial role in spark plug seat precision, affecting ignition system performance. Discover 7 powerful impacts of CNC machining on automotive, machine building, and automotion applications. Introduction CNC Machining is essential for producing high-precision spark plug seats that directly influence ignition system performance. Poorly machined seats can lead to misfires, reduced engine […]

CNC Machining plays a crucial role in producing precision spark plug seats. Explore 10 essential CNC machining processes for automotive, machine building, and automation industries to ensure durability and reliability. Introduction (Focus Keyword at the beginning) CNC Machining is essential for producing precision spark plug seats that meet the rigorous demands of automotive engines. High-precision […]

CNC Machining plays a critical role in producing high-quality water pump housings. Discover 12 essential CNC machining processes that ensure precision and reliability in automotive, machine building, and automation industries. Introduction (including Focus Keyword at the beginning):CNC Machining is the backbone of modern water pump housing production, enabling precision, consistency, and reliability in critical applications. […]

CNC Machining delivers the accuracy, surface integrity, and reliability required for precision oil pump housings used in demanding automotive and industrial environments. CNC Machining is the critical foundation behind precision oil pump housing manufacturing, where failure is not just expensive, but potentially catastrophic for automotive, oil & gas, and heavy-duty machinery systems. Introduction: Why Oil […]

CNC Machining enables the precision manufacturing of complex turbocharger housings by controlling geometry, surface quality, and dimensional accuracy for high-performance automotive applications. CNC Machining is the decisive technology behind modern turbocharger housing manufacturing, where complex internal geometry, extreme rotational speed, and thermal-mechanical stress converge into one of the most demanding challenges in automotive production. Introduction: […]

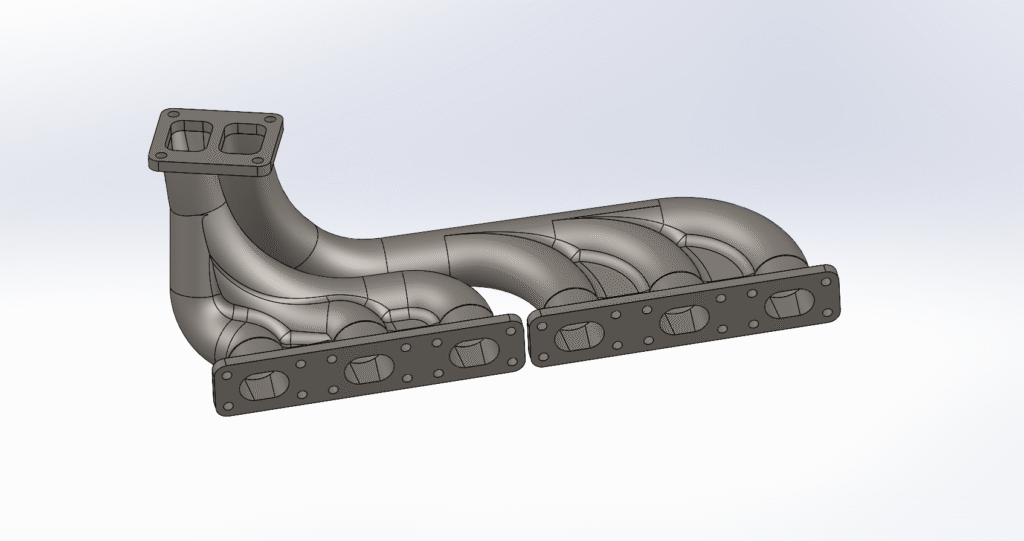

CNC Machining is the foundation of modern exhaust manifold manufacturing, especially when thermal stress, fatigue failure, and long-term durability become critical challenges in high-temperature automotive environments. Introduction: Why Thermal Stress Makes Exhaust Manifolds a High-Risk Component Exhaust manifolds operate in one of the harshest environments inside an engine. Continuous exposure to extreme temperatures, thermal cycling, […]

CNC Machining is an essential process in producing precise cavities for intake manifolds, directly affecting airflow efficiency, engine performance, and long-term reliability in automotive, machine building and automotion industries. Intake manifold machining requires both precision and repeatability to ensure optimal airflow paths, sealing integrity, and compatibility with cylinder heads. Drawing on industry research, case studies, […]