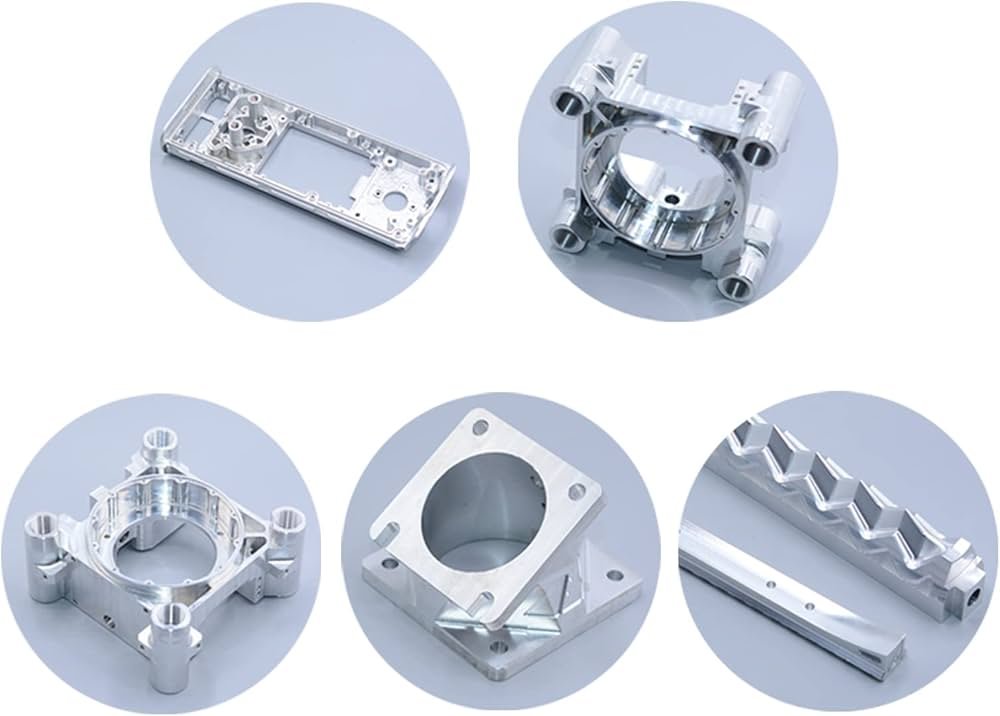

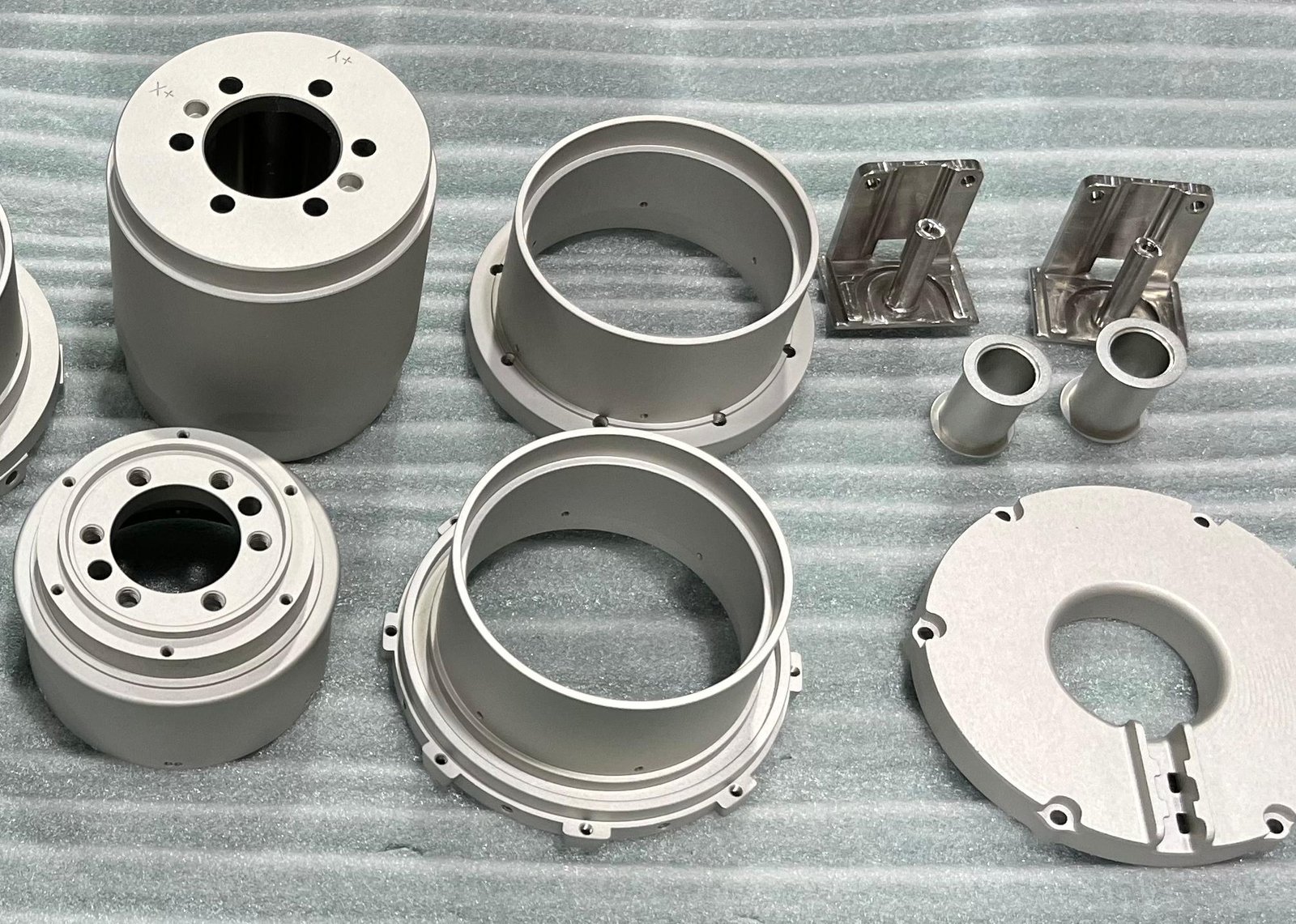

Pemesinan CNC plays a pivotal role in the medical device manufacturing industry, ensuring unparalleled precision, customization, and efficiency. Drawing insights from industry-leading resources, this article delves into the top 10 ways CNC precision machining enhances medical device production. For over 12 years, CNCRUSH, a China-based factory, has specialized in providing high-quality CNC machining services, including CNC Milled parts and CNC Turned parts, catering to industries such as automotive, machine building, and automation.

1. Pemesinan CNC: Achieving Unmatched Precision in Medical Devices

In the medical field, precision is paramount. CNC precision machining offers exceptional accuracy, producing components with tight tolerances essential for medical devices. This precision ensures the reliability and safety of instruments used in critical procedures.

2. Pemesinan CNC: Facilitating Customization for Patient-Specific Solutions

CNC precision machining enables the production of customized medical components tailored to individual patient needs. This capability is crucial for creating implants and prosthetics that fit perfectly, enhancing patient comfort and treatment outcomes.

3. Pemesinan CNC: Enhancing Efficiency in Prototyping and Production

The rapid prototyping capabilities of CNC machining accelerate the development of medical devices. Manufacturers can quickly iterate designs, reducing time-to-market and ensuring timely delivery of essential medical equipment.

4. Pemesinan CNC: Ensuring Compliance with Medical Standards

CNC machining processes are designed to meet stringent medical industry standards, including ISO 13485. This compliance guarantees that manufactured components adhere to quality and safety regulations, instilling confidence in healthcare providers.

5. Pemesinan CNC: Supporting a Wide Range of Biocompatible Materials

CNC precision machining is compatible with various biocompatible materials, such as titanium, stainless steel, and medical-grade plastics. This versatility allows for the production of diverse medical components suitable for different applications.

6. Pemesinan CNC: Delivering Consistency in Mass Production

For large-scale manufacturing, CNC precision machining ensures consistent quality across all produced units. This consistency is vital for medical devices, where uniformity can impact the effectiveness and safety of treatments.

7. Pemesinan CNC: Reducing Waste and Promoting Sustainability

Presisi mesin CNC meminimalkan limbah material, berkontribusi pada praktik manufaktur yang lebih berkelanjutan. This efficiency not only conserves resources but also reduces production costs.

8. Pemesinan CNC: Enhancing Surface Finish for Medical Applications

The superior surface finish achieved through CNC precision machining is essential for medical devices, reducing the risk of bacterial contamination and improving the longevity of implants and instruments.

9. Pemesinan CNC: Enabling Complex Geometries in Device Design

Advanced CNC precision machining techniques allow for the creation of intricate designs and complex geometries required in modern medical devices, expanding the possibilities for innovative healthcare solutions.

10. Pemesinan CNC: Providing Reliable Solutions for Critical Applications

The reliability of CNC precision machining ensures that medical devices function as intended in critical applications, such as surgical procedures and life-support systems, where failure is not an option.

Table 1: Advantages of CNC precision Machining in Medical Device Manufacturing

| Keuntungan | Keterangan |

|---|---|

| Presisi | Achieves tight tolerances essential for medical applications |

| Kustomisasi | Allows for patient-specific device production |

| Efisiensi | Speeds up prototyping and reduces time-to-market |

| Compliance | Meets stringent medical industry standards |

| Keserbagunaan Bahan | Compatible with various biocompatible materials |

| Konsistensi | Ensures uniform quality in mass production |

| Keberlanjutan | Minimizes material waste and reduces costs |

| Permukaan Selesai | Provides superior finishes for hygiene and durability |

| Geometri Kompleks | Enables intricate designs for advanced medical devices |

| Keandalan | Delivers dependable performance in critical medical applications |

Table 2: Common Medical Components Produced via CNC Machining

| Tipe Komponen | Contoh Aplikasi |

|---|---|

| Implan | Orthopedic and dental implants |

| Instrumen Bedah | Scalpels, forceps, and retractors |

| Peralatan Diagnostik | Housings and components for imaging devices |

| Prosthetics | Custom-fitted limb prostheses |

| Kateter | Precision components for vascular access |

Bagian FAQ

Q1: Why is CNC manufacturing preferred in medical device manufacturing?

A1: CNC manufacturing offers unparalleled precision, customization, and efficiency, making it ideal for producing high-quality medical components that meet stringent industry standards.

Q2: What materials are commonly used in CNC manufacturing for medical devices?

A2: Common materials include titanium, stainless steel, and medical-grade plastics, all of which are biocompatible and suitable for various medical applications.

Q3: How does CNC manufacturing contribute to faster medical device development?

A3: CNC manufacturing enables rapid prototyping, allowing for quick iterations and adjustments in the design phase, thereby reducing the overall development timeline.

For over 12 years, CNCRUSH has been a trusted provider of high-quality CNC manufacturing services, specializing in CNC Milled parts and CNC Turned parts. Our expertise ensures that medical device manufacturers receive components that meet the highest standards of precision and reliability. Apakah Anda berada di industri otomotif, pembuatan mesin, atau otomasi, CNCRUSH is committed to delivering exceptional CNC machining solutions tailored to your needs.