Pemesinan CNC is revolutionizing the automotive industry by enabling high-precision, high-efficiency production of automotive parts. This comprehensive guide explores cutting-edge strategies, advanced technologies, and data-driven approaches that optimize every aspect of automotive component manufacturing. Drawing from industry-leading resources and deep market insights, we detail how high-quality Layanan Pemesinan CNC can transform automotive production and support critical sectors like machine building and automotion. At CNCRUSH, our 12 years of expertise as a leading China CNC factory ensures we provide exceptional Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC for automotive and related industries.

In this guide, we present ten in-depth sections that break down the fundamentals, advanced techniques, and economic benefits of CNC machining in the automotive industry. Each section is enriched with analytical insights, emotional perspectives, and actionable data—including two analytical tables and a comprehensive FAQ section. Whether you are aiming to reduce production costs, improve quality, or integrate the latest digital innovations, read on for a masterclass on how CNC Machining optimizes automotive part production.

1. CNC Machining Service Fundamentals for Automotive Parts Production

A robust Layanan Pemesinan CNC forms the backbone of any high-quality automotive parts production line. Fundamental to this process is an understanding of how CNC machining parameters interact to produce precise, repeatable components.

-

Machine Rigidity and Calibration: Every automotive part production begins with machine stability. Rigid fixtures, periodic calibration, and high-speed spindles are crucial in minimizing vibrations that can compromise precision.

-

Pemilihan Alat: The choice of cutting tools—ranging from coated carbide end mills to specialized inserts—affects both surface finish and dimensional accuracy. Matching the tool to the material (e.g., steel, aluminum, or composite alloys) is essential.

-

Optimasi Proses: Utilizing advanced CAM software to simulate operations can reduce errors and optimize toolpaths. Accurate simulation translates to fewer downtimes and a consistently high-quality output.

By mastering these basics, a Layanan Pemesinan CNC provider can manufacture reliable Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC that meet the rigorous standards of automotive, machine building and automotion industries. When executed correctly, these fundamentals drive increased throughput and enhanced product quality—yielding both economic and performance benefits.

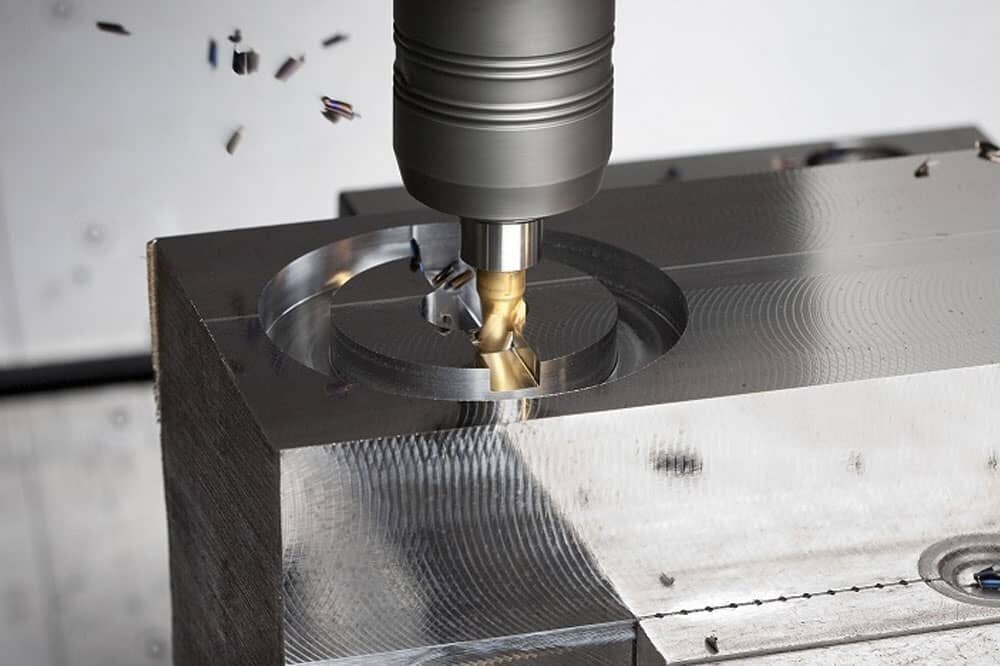

2. Optimizing CNC Milled Parts for Automotive Components

High-performance Bagian yang digiling CNC are essential for the precise assembly of automotive systems. Optimizing the milling process not only enhances the final product’s quality but also significantly reduces production times and costs.

-

Toolpath Strategies: Implementing optimized toolpaths minimizes machining errors by reducing non-cutting movements and ensuring smooth transitions. Advanced CAM simulation technologies help in testing various scenarios before production starts.

-

Parameter Control: Fine-tuning cutting speed, feed rate, and step-over values enhances the surface finish and dimensional accuracy. These adjustments are particularly important when working with complex automotive geometries.

-

Jaminan Kualitas: In-line quality inspection and real-time data monitoring are imperative for catching deviations early. This ensures that every milled component meets or exceeds industry standards.

Adopting these practices leads to robust Bagian yang digiling CNC that are reliable even in the most demanding automotive applications. Manufacturers witness a remarkable reduction in scrap and rework, boosting both quality and efficiency—a positive stride for any Layanan Pemesinan CNC.

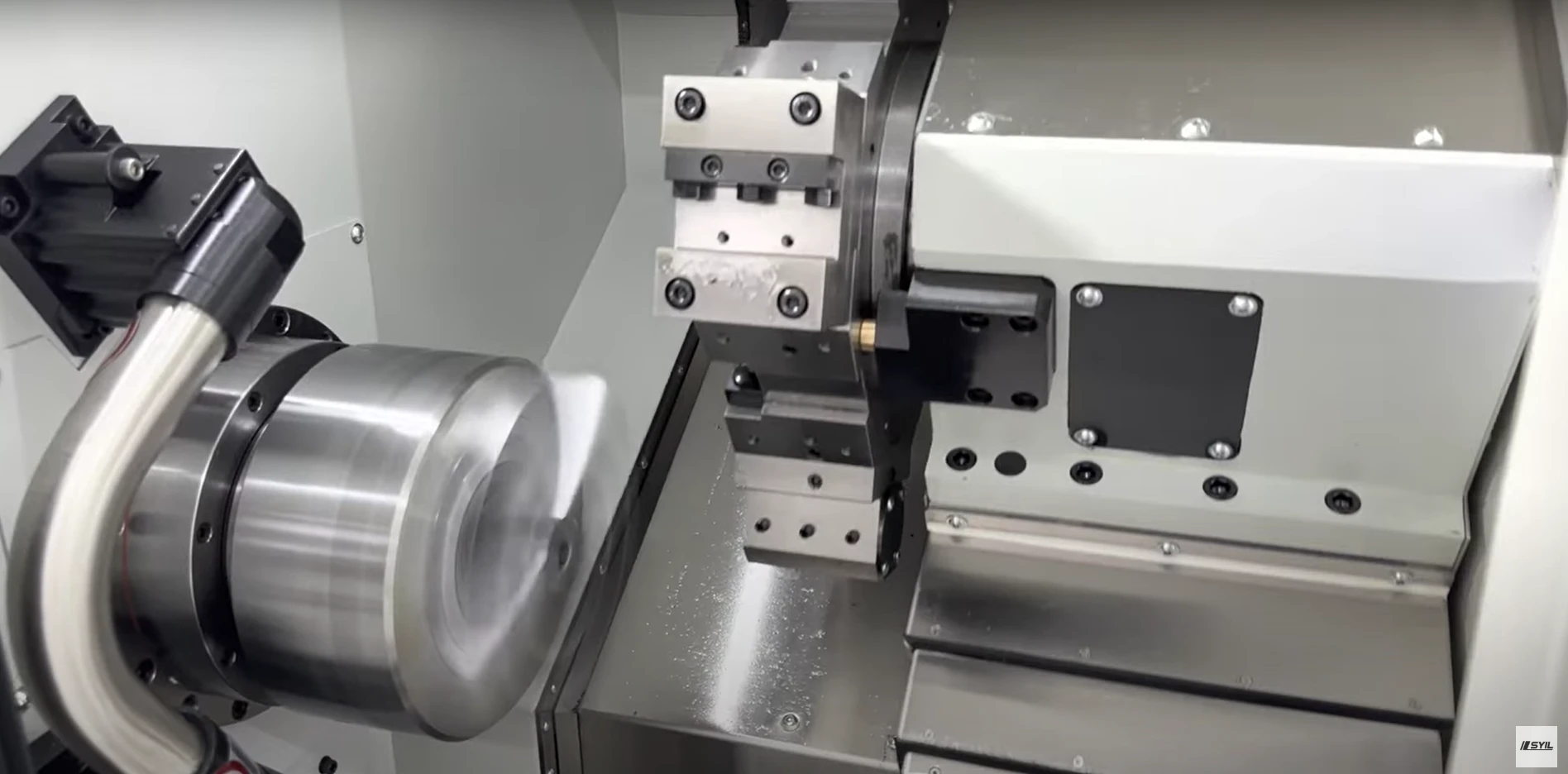

3. Enhancing CNC Turned Parts Quality in Automotive Production

Producing stellar Bagian-bagian yang diputar CNC is equally critical, especially for automotive components that require cylindrical shapes and rotational symmetry. Precision in turning operations directly influences the overall performance of the automotive assembly.

-

Balancing Cutting Dynamics: Finding the optimal balance between cutting speed and feed rate ensures that the turning process maintains dimensional accuracy. Incorrect settings can lead to issues such as chatter or tool deflection.

-

Custom Tooling Solutions: High-quality, custom-designed turning tools help to achieve smoother finishes and prolong tool life, which is critical for high-volume production.

-

Stabilitas proses: Consistent in-process monitoring and closed-loop control systems help in identifying and correcting deviations immediately. This stability is imperative in preventing run-out errors and material wastage.

Implementing these advanced turning techniques results in Bagian-bagian yang diputar CNC that meet the high tolerances required in automotive manufacturing. Such improvements resonate positively across production lines, making every component a testament to cutting-edge Layanan Pemesinan CNC.

4. Advanced CNC Machining Service Techniques in the Automotive Industry

Modern automotive manufacturing relies heavily on the integration of advanced Layanan Pemesinan CNC techniques that leverage digital innovation and automation.

-

Pemantauan proses real-time: The implementation of IoT sensors and digital twins enables constant monitoring of key parameters like temperature, vibration, and tool wear. This real-time feedback allows for immediate adjustments to maintain optimal cutting conditions.

-

Sistem Kontrol Adaptif: Adaptive systems automatically adjust feed rates and cutting speeds in response to real-time data, ensuring optimal performance without operator intervention.

-

Analisis Prediktif: Utilizing big data analytics and AI algorithms can forecast tool wear and potential failures, thereby reducing downtime and increasing production consistency.

Integrating these advanced methodologies not only accelerates the production of Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC but also helps automotive manufacturers meet increasingly complex quality requirements. This digital evolution in Pemesinan CNC embodies a highly positive sentiment for technology’s role in modern manufacturing.

5. Data-Driven CNC Milled Parts Optimization for Auto Manufacturing

Data analytics plays a pivotal role in refining the performance of Bagian yang digiling CNC production. Leveraging statistical process control and real-time monitoring leads to sustained quality and operational excellence.

-

Process Analytics: By collecting data on cutting conditions and outcomes, manufacturers can pinpoint inefficiencies and implement improvements. This analytical approach minimizes waste and enhances overall product consistency.

-

Perbaikan Berkesinambungan: Using historical data to establish benchmarks and KPIs enables continuous process refinement, resulting in lower rework rates and higher first-pass yields.

-

Pelaporan Otomatis: Dasbor digital memberikan representasi visual dari kinerja permesinan, yang memungkinkan manajer mengambil keputusan dengan cepat.

Pengoptimalan berbasis data di Pemesinan CNC tidak hanya meningkatkan kualitas Bagian yang digiling CNC tetapi juga mendukung efisiensi produksi secara keseluruhan-keuntungan strategis untuk industri otomotif dan pembuatan mesin.

6. Solusi Suku Cadang Pembubutan CNC Cerdas untuk Rekayasa Presisi

Rekayasa presisi dalam manufaktur otomotif membutuhkan kualitas yang luar biasa dalam Bagian-bagian yang diputar CNCSolusi cerdas dan praktik pemesinan cerdas adalah kunci untuk mencapai hal ini.

-

Sensor dan Pemantauan Cerdas: Mengintegrasikan sensor canggih di dalam mesin CNC memungkinkan pelacakan yang akurat terhadap kondisi pahat dan kinerja pemotongan. Kecerdasan ini memudahkan adaptasi yang cepat terhadap anomali apa pun.

-

Penyesuaian Proses Khusus: Menyesuaikan parameter pemesinan berdasarkan persyaratan unik dari setiap kelompok komponen akan meningkatkan konsistensi dan kepatuhan terhadap spesifikasi desain.

-

Penyesuaian Berdasarkan Umpan Balik: Dengan menggunakan sistem umpan balik loop tertutup, operator dapat langsung menyesuaikan kecepatan potong dan pemakanan, sehingga memastikan bahwa hasil akhir Bagian-bagian yang diputar CNC secara konsisten memenuhi toleransi yang ketat.

Solusi cerdas ini membantu mempertahankan tingkat presisi yang tinggi dalam Bagian-bagian yang diputar CNC produksi, menjadikannya sangat diperlukan untuk aplikasi otomotif berkinerja tinggi. Pendekatan yang didukung data ini merupakan aspek penting dari Layanan Pemesinan CNC.

7. Otomatisasi dalam Layanan Pemesinan CNC untuk Efisiensi Otomotif

Otomasi mendefinisikan ulang bagaimana komponen otomotif diproduksi. Dalam bidang Pemesinan CNCsistem otomatis mendorong tingkat efisiensi dan konsistensi yang belum pernah ada sebelumnya.

-

Integrasi Robot: Robot dapat menangani tugas-tugas yang berulang seperti bongkar muat benda kerja, yang mengurangi waktu siklus dan kesalahan manusia. Penggantian alat otomatis juga berkontribusi secara signifikan terhadap produktivitas secara keseluruhan.

-

Kontrol Proses Digital: Otomatisasi model kembar digital dan simulasi proses memungkinkan produsen untuk memprediksi hasil operasi pemesinan sebelum produksi fisik dimulai.

-

Efisiensi Operasional: Otomatisasi menghasilkan siklus pemesinan yang lebih pendek, hasil yang lebih baik, dan kualitas yang konsisten pada keduanya Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC.

Integrasi otomatisasi dalam Pemesinan CNC menumbuhkan sentimen yang sangat positif dalam lingkungan produksi, karena tidak hanya meningkatkan produktivitas, tetapi juga meningkatkan presisi manufaktur secara keseluruhan-kunci untuk memenuhi tuntutan dinamis industri otomotif dan pembuatan mesin.

8. Inovasi Material dan Suku Cadang yang Digiling CNC dalam Desain Otomotif

Inovasi material terus mendorong batas-batas dari apa yang mungkin dilakukan dalam manufaktur otomotif. Kemajuan ini secara langsung berdampak pada produksi Bagian yang digiling CNCyang mempengaruhi kecepatan potong dan teknik pemesinan.

-

Paduan dan Komposit Ringan: Material modern, seperti paduan aluminium berkekuatan tinggi dan komposit canggih, memerlukan parameter pemesinan yang tepat untuk mempertahankan integritas struktural sekaligus mengurangi bobot.

-

Pengoptimalan Khusus Material: Setiap material menunjukkan sifat yang unik dalam hal kekerasan, konduktivitas termal, dan kemampuan mesin. Menyesuaikan kecepatan potong dan pemakanan dengan sifat-sifat ini memastikan hasil yang optimal.

-

Manfaat Lingkungan: Material yang lebih ringan dan lebih efisien berkontribusi pada penghematan bahan bakar dan emisi yang lebih rendah pada aplikasi otomotif, selaras dengan tujuan keberlanjutan global.

Kemampuan untuk mengerjakan material canggih ini dengan presisi tinggi adalah ciri khas dari Layanan Pemesinan CNCUnggul Bagian yang digiling CNC dengan demikian memainkan peran penting dalam mendorong gelombang inovasi desain otomotif berikutnya.

9. Menyeimbangkan Biaya dan Kualitas dalam Produksi Suku Cadang yang Dibubut CNC

Dalam setiap proses manufaktur, menyeimbangkan biaya dan kualitas sangatlah penting. Bagian-bagian yang diputar CNC produksi dapat membantu produsen otomotif mencapai penghematan biaya yang signifikan dengan tetap mempertahankan standar kualitas tinggi.

-

Strategi yang hemat biaya: Mengoptimalkan kecepatan potong dan laju pemakanan dapat menyebabkan keausan pahat dan konsumsi energi yang lebih rendah, yang secara langsung berdampak pada biaya produksi.

-

Output Berkualitas Tinggi: Berinvestasi dalam sistem kontrol kualitas memastikan bahwa setiap Bagian-bagian yang diputar CNC batch memenuhi standar industri otomotif yang ketat. Konsistensi ini meminimalkan pengerjaan ulang dan pengembalian, yang selanjutnya mengurangi biaya.

-

Laba atas Investasi: Investasi strategis dalam teknologi canggih dan otomatisasi menghasilkan manfaat biaya jangka panjang melalui peningkatan efisiensi, pengurangan waktu henti, dan volume produksi yang lebih tinggi.

Keseimbangan yang cermat antara biaya dan kualitas dalam Pemesinan CNC tidak hanya meningkatkan margin keuntungan tetapi juga meningkatkan reputasi pabrikan di pasar otomotif, pembuatan mesin, dan otomasi. Berkualitas tinggi Bagian-bagian yang diputar CNC dengan demikian menjadi pembeda yang sangat penting dalam lanskap yang kompetitif.

10. Bermitra dengan CNCRUSH: Layanan Pemesinan CNC Utama Anda untuk Keunggulan Otomotif

Pada CNCRUSH, we pride ourselves on delivering industry-leading Layanan Pemesinan CNC with over 12 years of expertise. Our state-of-the-art China CNC factory specializes in producing high-precision Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC tailored for automotive production, machine building, and automotion.

-

Unmatched Experience: With more than a decade of experience, CNCRUSH has developed custom CNC solutions that meet the most stringent quality requirements.

-

Teknologi Maju: Our facilities are equipped with the latest machining technologies and digital control systems, ensuring every part is produced with impeccable precision.

-

Tailor-Made Solutions: We offer custom CNC solutions that optimize cutting parameters to produce automotive components that exceed industry standards.

-

Jaminan Kualitas: Rigorous quality control and data-driven process monitoring guarantee that our Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC consistently meet the high demands of global clients.

Partnering with CNCRUSH means accessing superior Layanan Pemesinan CNC that drives tangible improvements in quality, efficiency, and cost management. We invite you to learn more about our customized solutions and discover how we can help optimize your automotive part production processes for explosive performance.

Table 1: Critical Parameters in Automotive CNC Machining

| Parameter | Jangkauan/Strategi Optimal | HTTPError: Response code 429 (Too Many Requests) | Metode Penyesuaian |

|---|---|---|---|

| Kecepatan Pemotongan | Optimized based on material and tool type | Balances tool life and production speed; reduces overheating | Monitored via digital control and sensor data |

| Tingkat Umpan | Tailored to ensure efficient chip removal | Enhances surface finish and dimensional accuracy | Adjusted dynamically using adaptive algorithms |

| Kedalaman Pemotongan | Shallow passes for precision and reduced deflection | Minimizes thermal load and potential errors | Fine-tuned through CAM simulation |

Table 2: Economic Impact of Optimized CNC Machining in Automotive Production

| Keuntungan | Hasil | Pengukuran | Strategi Implementasi |

|---|---|---|---|

| Mengurangi Keausan Alat | Lower frequency of tool replacements, increased life | Extended tool life and lower cost per unit | Regular monitoring and adaptive control |

| Improved Throughput | Shorter cycle times and increased production volume | Higher production rates and faster delivery | Automation and real-time process adjustments |

| Enhanced Surface Quality | Mengurangi kebutuhan untuk proses finishing sekunder | Lower scrap rates and higher first-pass yield | Optimized cutting parameters and quality control |

FAQs about How CNC Machining Optimizes Automotive Part Production

Q1: How does CNC Machining enhance the production of automotive parts?

A1: CNC Machining enables high precision, repeatability, and efficiency in producing automotive parts. Optimized cutting parameters, intelligent automation, and real-time monitoring ensure that both CNC Milled parts and CNC Turned parts are produced to exacting standards—reducing errors and enhancing quality.

Q2: What are the key benefits of partnering with a professional cnc machining service?

A2: Professional Layanan Pemesinan CNC providers offer advanced digital control, custom machining solutions, and rigorous quality assurance practices. These factors ensure superior quality in CNC Milled parts and CNC Turned parts, reduced production costs, and improved operational efficiency.

Q3: How can automation and digital control systems improve CNC Machining for automotive production?

A3: Automation and digital controls provide real-time monitoring of machining parameters, adaptive adjustments, and predictive maintenance. These technologies reduce errors, minimize downtime, and optimize cutting conditions, leading to enhanced quality and productivity in automotive component manufacturing.

Q4: Why is material selection critical in automotive CNC Machining?

A4: The choice of material influences cutting speed, tool wear, and surface finish. Tailoring machining parameters to specific material properties—such as those of high-strength alloys or lightweight composites—ensures that the resulting automotive parts meet design and performance specifications.

Q5: What makes CNCRUSH the ideal partner for automotive CNC Machining needs?

A5: With over 12 years of expertise, CNCRUSH offers customized, high-quality Layanan Pemesinan CNC backed by state-of-the-art technology. We specialize in producing exceptional Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC that cater to the demanding requirements of the automotive, machine building, and automotion industries.

Kesimpulan

Pemesinan CNC stands as a transformative force in automotive part production—delivering precision, efficiency, and unparalleled quality. By employing these ten groundbreaking strategies, automotive manufacturers can optimize machining parameters, enhance process control, and achieve outstanding outcomes in both Bagian yang digiling CNC Dan Bagian-bagian yang diputar CNC production. From fundamental machine setup to advanced digital control and predictive analytics, every aspect of CNC Machining contributes to cost-effective, high-quality production that meets the evolving demands of automotive, machine building and automotion industries.

Pada CNCRUSH, komitmen kami terhadap keunggulan Layanan Pemesinan CNC has made us a trusted partner in the global market. With over 12 years of specialized experience and a state-of-the-art facility in China, we deliver custom CNC solutions that empower automotive manufacturers to elevate their operations, reduce downtime, and achieve explosive performance gains.

Rangkullah wawasan revolusioner dan strategi inovatif yang dirinci dalam panduan ini untuk mengubah produksi suku cadang otomotif Anda. Biarkan CNCRUSH menjadi mitra utama Anda, dan rasakan betapa canggihnya Pemesinan CNC dapat membuka tingkat presisi, produktivitas, dan profitabilitas baru dalam proses manufaktur Anda.