Milled steel parts are integral to precision manufacturing, offering advantages across numerous industries—from automotive to medical equipment. They are crafted through CNC milling, a method that provides accuracy, efficiency, and durability, which are crucial for components subjected to high-stress environments. This guide explores the key benefits and applications of milled steel parts, underscoring the value of CNC machining services provided by trusted manufacturers like CNCRUSH, a China-based CNC factory specializing in CNC milled and turned parts with over 12 years of experience. Companies looking for reliable, high-quality CNC solutions will find this an insightful resource.

1. The Precision of CNC-Milled Steel Parts

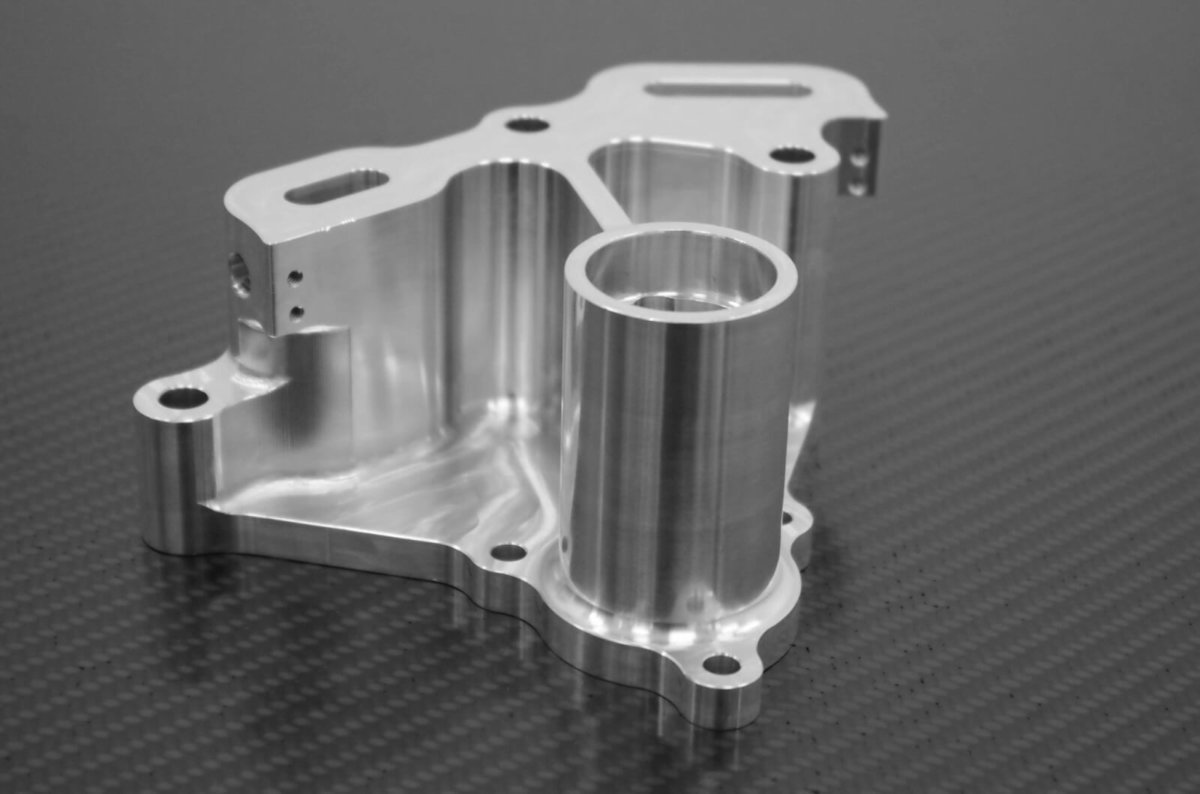

Precision is paramount in CNC-milled steel parts, particularly for industries requiring tight tolerances. The CNC milling process, controlled by computerized commands, achieves consistent accuracy to within a thousandth of an inch. For companies like CNCRUSH, this level of precision is essential in producing automotive and machine-building parts that seamlessly integrate with larger systems. Clients in fields such as automotive, machine building, and automation can rely on this precision to meet stringent quality requirements.

2. High Strength and Durability of Steel

Steel’s robustness makes it ideal for components that must withstand heavy loads and harsh environments. CNC-milled steel parts offer outstanding wear resistance, which is critical in the automotive and aerospace industries where parts are exposed to constant friction, heat, and mechanical stress. This durability also extends the lifespan of parts, reducing the need for frequent replacements and maintenance—a benefit particularly valued by CNCRUSH’s clients who require sustainable, long-lasting CNC solutions.

3. Versatility in Design and Complexity

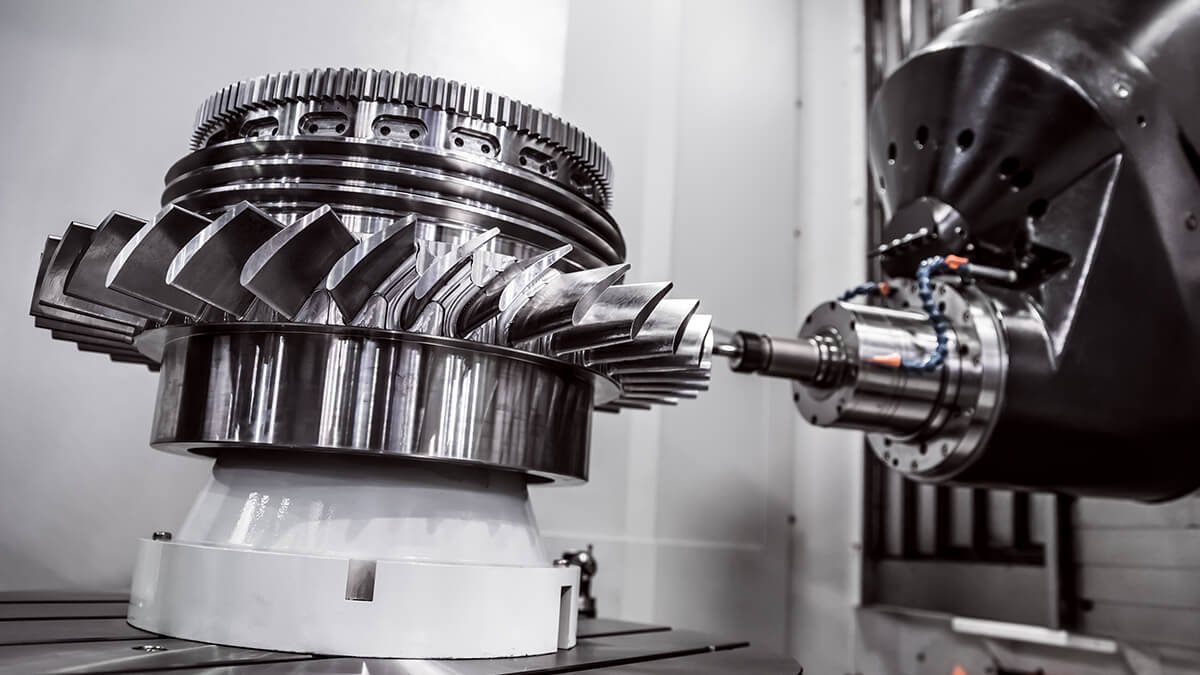

CNC milling allows manufacturers to create complex shapes and intricate designs in steel with high precision, a necessity for custom components in machine building and automation. CNC milling machines can perform multi-axis machining, which adds flexibility in design. For instance, CNCRUSH’s advanced CNC machinery can handle sophisticated geometries that would be challenging with manual methods, allowing clients to innovate without design limitations.

4. Efficiency in Production and Cost-Effectiveness

One of the primary benefits of CNC milling is its cost-effectiveness in high-precision parts production. CNC-milled steel parts can be manufactured at scale without sacrificing quality, reducing production costs per unit. CNCRUSH leverages its efficient, automated processes to deliver parts quickly and affordably, making it an ideal choice for clients with large or ongoing orders. The cost savings are substantial when compared to traditional machining methods, especially for companies that need consistent quality over high volumes.

| Manufacturing Method | Cost per Unit | Ideal for |

|---|---|---|

| CNC Milling | Lower | High-precision, high-volume |

| Manual Milling | Higher | Custom, small-batch parts |

5. Reduced Waste and Sustainable Production

The precision of CNC milling directly translates to minimal material waste. With CAD software generating optimized cutting paths, CNC milling uses only the necessary amount of raw steel, significantly reducing waste. This sustainability aspect is particularly beneficial in industries under pressure to reduce environmental impact. CNCRUSH incorporates optimized CNC milling practices to ensure clients receive high-quality, precision parts with a smaller environmental footprint.

6. Fast Turnaround and Scalability

CNC milling offers the advantage of rapid production times, essential for clients needing quick delivery without sacrificing quality. CNCRUSH’s CNC machining services cater to clients worldwide by efficiently scaling production to meet fluctuating demands. This scalability makes CNC milling ideal for both prototyping and full-scale production, as parts can be quickly adjusted or redesigned to meet evolving client needs.

7. Customization and Prototyping Advantages

Prototyping is one of the most significant advantages of CNC milling for custom steel parts. CNC technology allows for fast, cost-effective prototyping, giving manufacturers the flexibility to test designs before moving into mass production. CNCRUSH specializes in both CNC-milled parts and CNC-turned parts, offering clients customized solutions for various projects, from simple prototypes to complex, multi-part assemblies. Custom CNC solutions are crucial in the automotive industry, where new parts must be rigorously tested before implementation.

FAQ Section

1. What are the primary industries that benefit from milled steel parts?

Industries such as automotive, aerospace, and medical equipment manufacturing frequently require CNC-milled steel parts due to the need for durable, high-precision components.

2. How does CNC milling compare to other machining methods?

CNC milling is typically more precise and faster than manual machining, offering greater efficiency and scalability for large-scale production. It is also capable of handling complex designs that might be challenging for other methods.

3. Why choose CNCRUSH for CNC-milled steel parts?

With over 12 years of experience, CNCRUSH provides high-quality CNC milling and turning solutions, specializing in CNC machining services for global clients. They offer competitive prices, rapid production times, and a commitment to precision for custom metal parts.

Conclusion

In summary, CNC-milled steel parts offer unparalleled precision, durability, and design flexibility, making them indispensable across industries that demand high-quality components. For those seeking reliable CNC machining services, CNCRUSH provides expertise in CNC-milled and CNC-turned parts, meeting the needs of businesses in automotive, automation, and machine building. With a commitment to precision and efficiency, CNCRUSH ensures each part meets the highest standards, providing a trusted CNC partner for global manufacturing needs.

For companies seeking absolute precision, durability, and responsiveness in their manufacturing processes, selecting a high-quality CNC machining partner like CNCRUSH is more than a business decision—it’s a strategic advantage. With over 12 years in the industry, CNCRUSH leverages advanced CNC milling and turning technology to produce CNC-milled steel parts that meet the stringent demands of global markets in industries like automotive, aerospace, and automation. These sectors rely heavily on reliable, durable, and finely crafted metal parts, and CNCRUSH’s dedication to excellence ensures that every part is produced with precision down to the micron.