Automotive manufacturing relies on efficiency, accuracy, and cost-effectiveness to remain competitive in today’s market. CNC machining—especially when applied to materials like aluminum—has proven transformative for automotive production, from reducing material waste to increasing production speed and precision. Companies like CNCRUSH, a China-based factory specializing in CNC Milled and CNC Turned parts, bring over 12 years of expertise to meet the automotive industry’s high demands. This article dives into the specific ways CNC machining reduces production costs while improving quality, making it an essential process in automotive manufacturing.

1. CNC Machining for Automotive Manufacturing: Precision at Scale

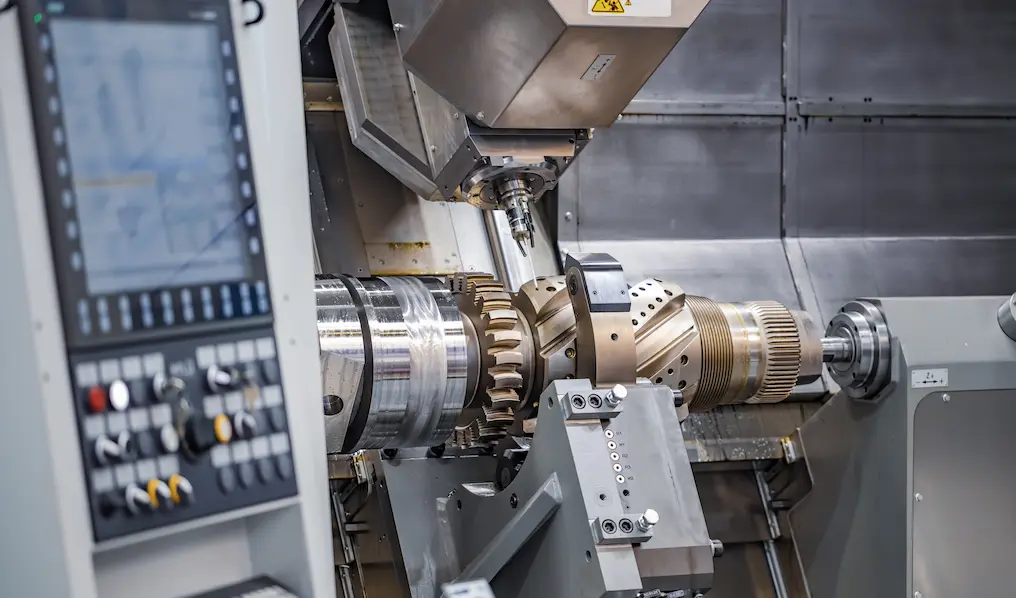

In automotive manufacturing, the need for high-precision parts at scale is critical. CNC machining delivers this precision through computer-controlled processes that can achieve micrometer-level accuracy. CNCRUSH’s CNC machining service, for instance, ensures each part meets exacting standards, reducing rework costs and enhancing assembly compatibility.

2. Cost Savings Through Reduced Material Waste

CNC machining optimizes the cutting path, which minimizes material waste—a cost-saving benefit particularly evident in expensive metals like aluminum. CNCRUSH’s CNC milling and turning processes allow manufacturers to achieve more parts per material unit, making the most out of raw materials and significantly reducing costs over large production runs. By leveraging CNC technology, Automotive Manufacturing companies can limit scrap and maximize the use of each metal blank.

3. Enhanced Speed and Production Efficiency

CNC machines operate at much faster speeds than manual methods, enabling manufacturers to meet tight deadlines without compromising quality. For CNCRUSH, high production speeds mean clients in the automotive sector receive parts quickly, supporting just-in-time manufacturing models that minimize inventory costs. CNC machining’s automation also allows continuous operation with minimal downtime, further enhancing production efficiency.

| Manufacturing Method | Typical Lead Time | Production Efficiency |

|---|---|---|

| CNC Machining | Short | High |

| Manual Machining | Longer | Moderate |

4. Consistent Quality for Mass Production

Automotive parts require not only high quality but also consistency across thousands of units. CNC machining excels at delivering identical parts in large quantities, eliminating the variability that can arise from manual machining. CNCRUSH’s CNC machining service guarantees that each part produced matches specifications, reducing inspection time and costs while ensuring seamless assembly.

5. Lower Labor Costs Through Automation

Automating the machining process with CNC technology reduces the need for manual labor, which in turn lowers operational costs. Skilled operators are still required to set up and oversee CNC machines, but the intensive, repetitive labor is minimized, resulting in a lower cost per part. CNCRUSH’s automated CNC solutions support automotive clients in reducing labor expenses, which is essential in high-volume production environments.

6. Flexibility for Complex and Custom Designs

Automotive manufacturers often need complex parts with specific geometries, especially for newer vehicle models. CNC machining allows for intricate designs that would be difficult or impossible to achieve with traditional methods. CNCRUSH’s advanced CNC milling and turning capabilities allow clients to quickly adapt to design changes without incurring excessive costs, which is particularly beneficial during prototyping or when new models are introduced.

7. Reduced Maintenance Costs for Long-Lasting Tools

CNC machines are built for durability and require less frequent maintenance compared to traditional manufacturing tools. This longevity translates to lower maintenance costs over time. CNCRUSH’s CNC machinery is equipped with cooling systems and automated tool change capabilities, which help prevent tool wear and ensure a longer lifespan, contributing to consistent production quality and cost savings.

8. Energy Efficiency in CNC Processes

CNC machining is more energy-efficient than traditional machining because it uses optimized programming that reduces idle time and energy waste. For CNCRUSH, energy-efficient CNC processes mean lower operational costs, which can be passed on to automotive clients in the form of more affordable CNC machining services.

9. Increased Productivity with Multi-Axis Capabilities

Multi-axis CNC machines, such as 5-axis CNC milling, enable complex machining operations to be performed in a single setup. This capability drastically reduces setup times and increases productivity, as multiple features can be machined on a part without repositioning. CNCRUSH’s multi-axis CNC technology ensures high productivity, especially valuable in automotive manufacturing where complex parts must be produced quickly.

10. Seamless Prototyping to Full-Scale Production Transition

In the automotive industry, prototyping and testing new designs is crucial for success. CNC machining allows for quick and affordable prototyping, providing a direct path from prototype to full-scale production without requiring a new setup. CNCRUSH’s prototyping services support Automotive Manufacturing clients in validating designs efficiently before ramping up production, helping to streamline the process and reduce costly redesigns.

FAQ Section

1. How does CNC machining benefit automotive manufacturing?

CNC machining provides precision, efficiency, and cost savings by producing high-quality parts with reduced waste, lower labor costs, and faster production times.

2. Can CNC machining handle custom Automotive Manufacturing?

Yes, CNC machining is ideal for custom automotive parts, as it can accommodate complex designs and adjust quickly to new specifications without additional setup costs.

3. Why should automotive companies choose CNCRUSH for CNC machining services?

With over 12 years of experience, CNCRUSH specializes in CNC milled and turned parts, offering high-quality, efficient, and cost-effective solutions that meet the specific needs of the automotive industry.

Conclusion

CNC machining has reshaped automotive manufacturing by offering precise, cost-effective solutions essential to high-volume production. By reducing waste, labor, and operational costs, CNC technology enables manufacturers to produce high-quality components while keeping expenses in check. For automotive businesses looking to maximize their efficiency and reduce production costs, CNCRUSH offers expert CNC machining services, with a commitment to quality, precision, and sustainability. From prototyping to full production, CNCRUSH supports automotive manufacturers globally, delivering advanced CNC-milled and CNC-turned parts that keep pace with the industry’s evolving needs.