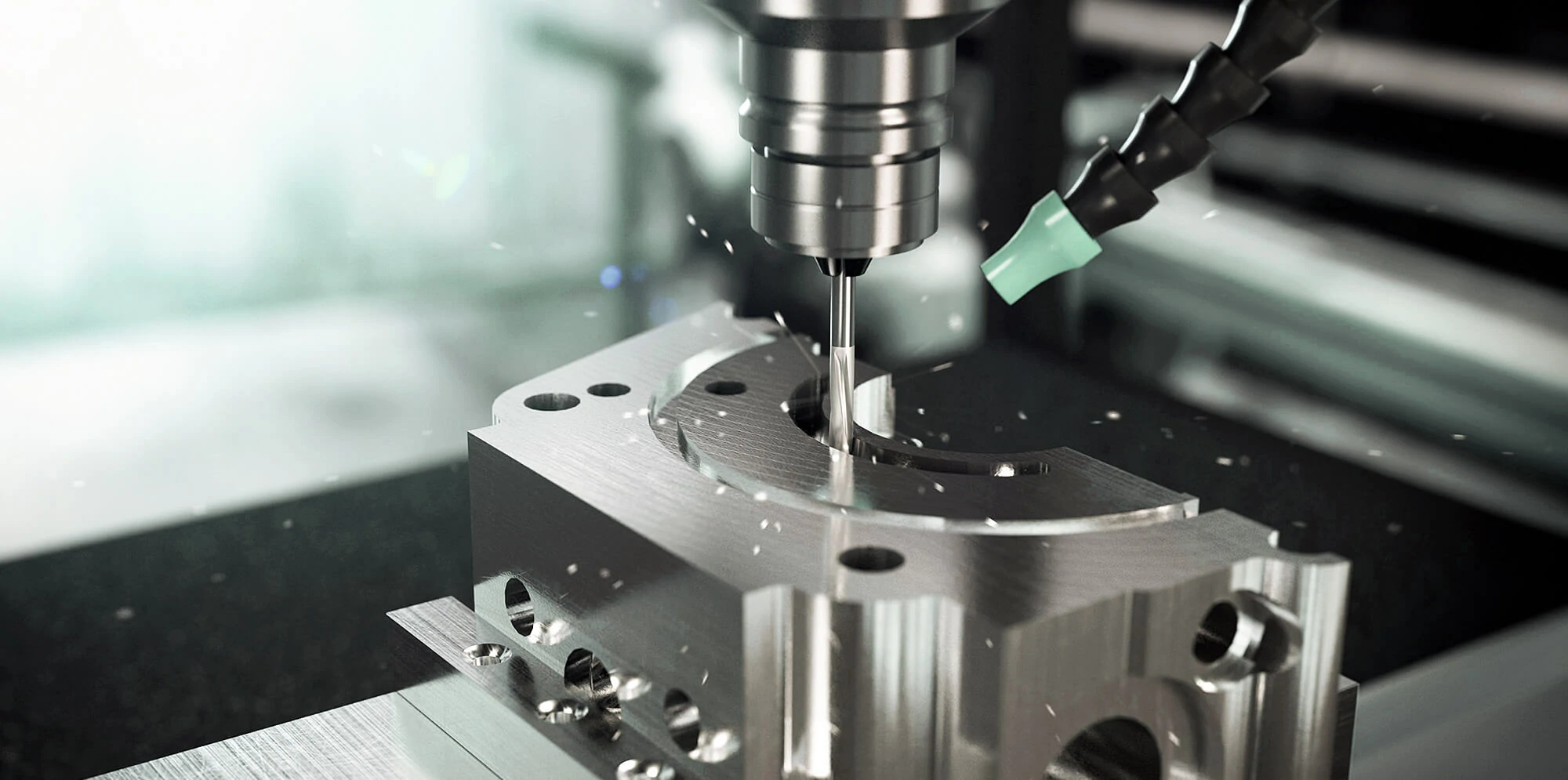

CNC Milled parts

At CNCRUSH, we pride ourselves on delivering high quality CNC milled parts while maintaining competitive pricing.

At CNCRUSH, we pride ourselves on delivering high quality CNC milled parts while maintaining competitive pricing.

A 3-axis machine moves along three linear axes: X, Y, and Z. It is primarily used for machining flat surfaces or simple geometries. While efficient and cost-effective, it lacks the capability to handle complex contours or undercuts.

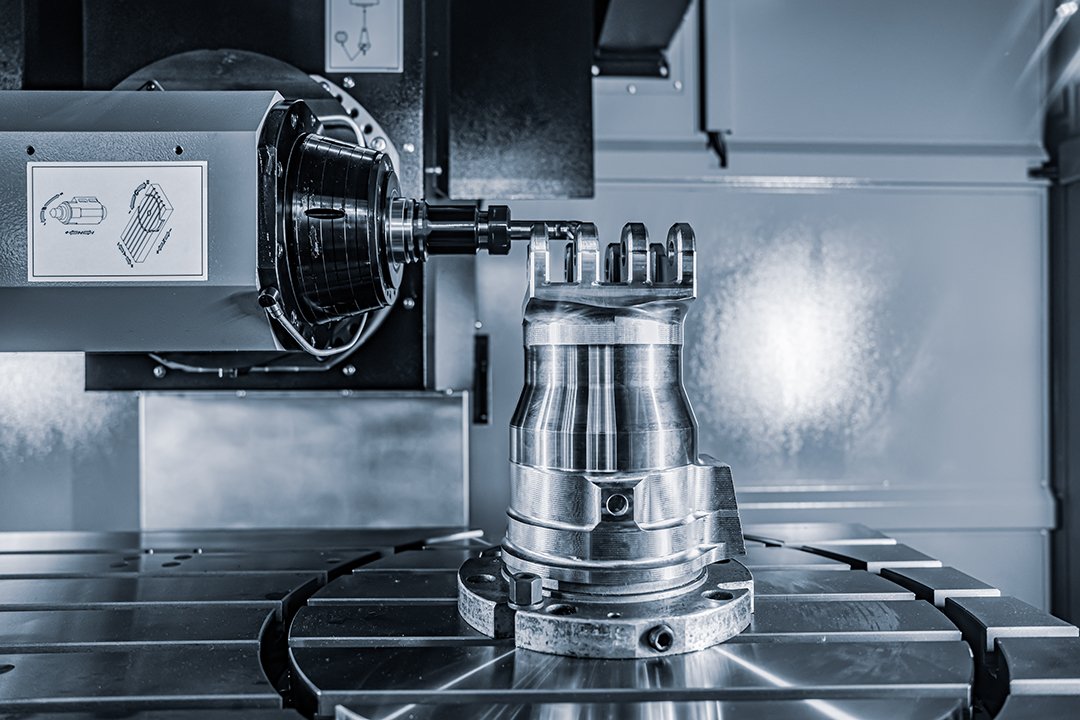

A 4-axis machine includes three linear axes (X, Y, Z) and one rotational axis (usually around X or Y). It enables machining on multiple sides of a part without repositioning, making it ideal for cylindrical objects or intricate side features.

A 5-axis machine offers three linear axes (X, Y, Z) and two rotational axes, enabling machining from virtually any angle. It is essential for producing intricate, high-precision parts like aerospace components and medical devices, reducing setups and improving efficiency.

At CNCRUSH, with 12 years of industry experience, our skilled team operates advanced machine tools from trusted brands to deliver precision-milled parts. Utilizing modern measuring equipment and professional CAM systems, we ensure the high standards in CNC milling.

This section has been designed to address frequently asked questions and provide clarity on any concerns you may have about milling parts at CNCRUSH. Here, you’ll find detailed information to help you better understand our order fulfillment process and how we approach projects requiring precision milling services, ensuring we meet your goals efficiently and effectively.

We We can achieve an accuracy of 0.005mm, depending on the specific product requirements..

Yes, at CNCRush, we accept orders for combined milling and turning operations. These are primarily handled by our advanced lathes with milling capabilities.

Our machine park features advanced milling machines from top brands like Hermle, Okuma, and Fanuc. These 3-, 4-, and 5-axis machines allow us to produce parts with high accuracy and productivity.

We use fully automated band saws to cut material for milling, handling cross-sections up to 300 x 300 mm, ensuring efficiency for both small and large orders.

The cost of CNC milling is influenced by material type, part complexity, tooling costs, batch size, and surface finish requirements. Additionally, many projects require custom tooling, which can also impact pricing.

Our standard lead time is usually 5-10 working days, depending on the complexity of the product and the order quantity..